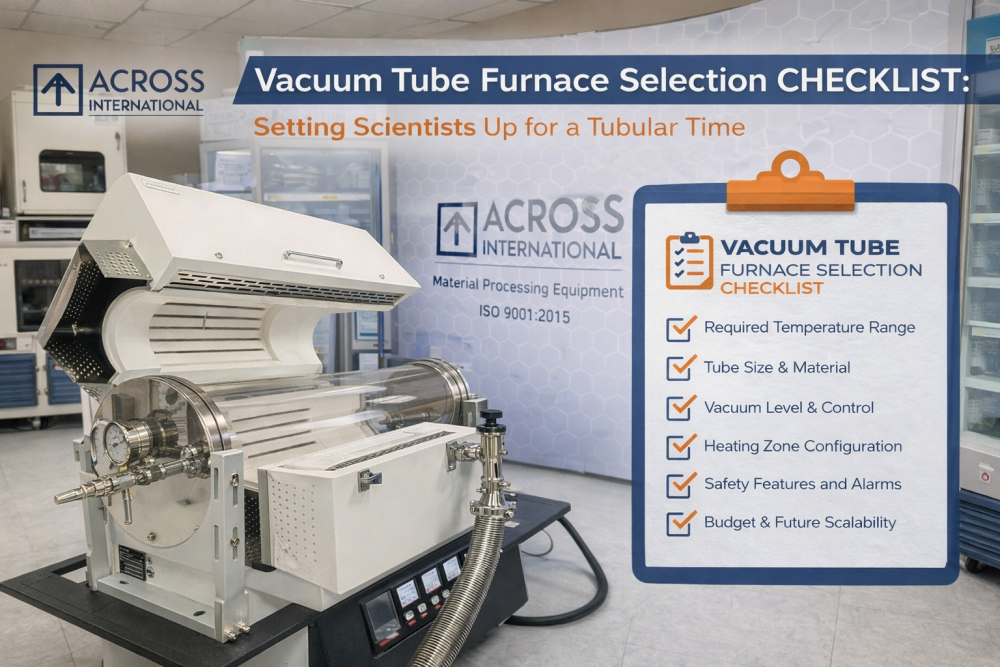

Most vacuum tube furnace failures don’t happen during operation. They happen during the selection and purchasing process; as the saying goes, “the most expensive piece of equipment is the one you buy twice.”

Across International has decades of experience building successful laboratories in the R&D, pilot and production stages, as well as routinely works with labs and teams that come to us after a furnace has already failed them, whether it be mechanically, functionally, strategically, or some combination. The system technically “works,” but it is essential for a laboratory or plant and its supplier to align on the best equipment for optimal performance for the purpose.

By the time this opportunity cost becomes obvious, the real cost is no longer even the furnace itself. It’s lost samples, time, rewritten, unsuccessful procedures, missed milestones, and ultimately, in many cases, the need to repurchase a second system within 6–24 months.

Worst case scenario: it is lost credibility or faith in a project.

We have prepared this report to prevent that exact outcome; let us be your guide to vacuum tube furnace success and prosperity. If you are specifying the best furnace for materials research, process development, or pilot-scale thermal processing, the decisions you make now will determine whether your system becomes a long-term platform — or an expensive bottleneck. We are happy to be partners in that process.

Tube Furnace Types & Selecting the Style for Your Process

First, quickly cover the different types of tube furnace heating technologies to select from, and where each shine in the field, to pick the perfect tool for your technical requirements:

1. VTF Vertical Tube Furnaces and the advantages of gravity

Vertical orientation can help minimize particle settling, particularly with heavy, light or dissimilar gases and vapors, as well as sample deformation, and potential uneven coating, critical for powders, fibers, and deposition processes.

Some use cases include:

- Chemical Vapor Deposition (CVD) of nanotubes, nanowires, and thin films

- Powder calcination and annealing battery cathodes, catalysts and specialty materials

- Thermal oxidation and reduction of fine powders, samples and reactions

- Fiber and filament heat treatment, such as of carbon and ceramic fibers

Controlled atmosphere sintering of vertically suspended samples

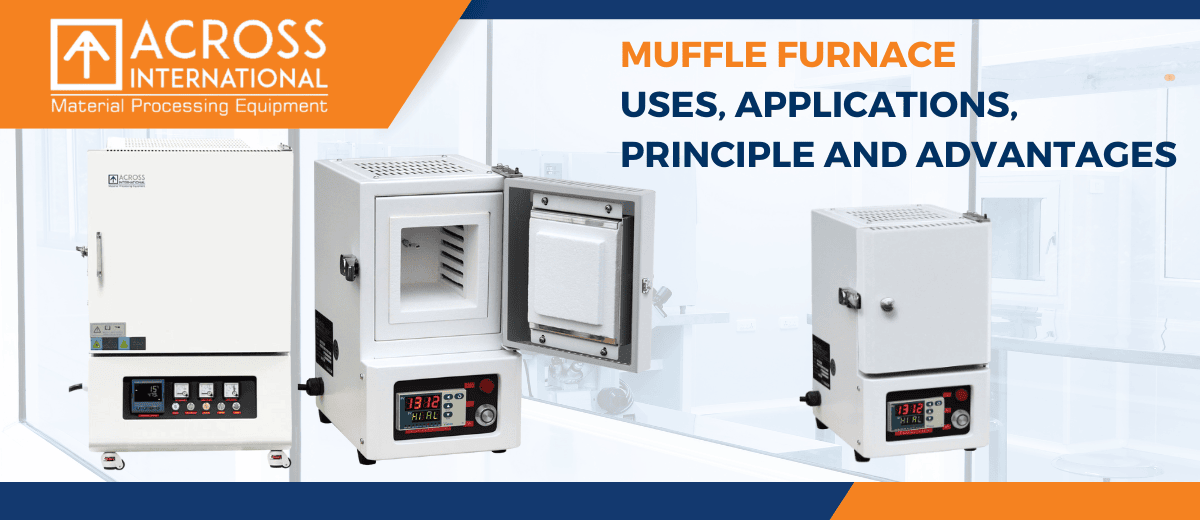

2. STF and TF Horizontal Tube Furnaces with resistive heating elements

The most cost-effective and commonly found tube furnace in any laboratory, typically achieving heating rates of 10-30°C/min maximum, or lower depending on standard operating procedure.

Examples of applications tube furnaces are commonly called upon for:

- Annealing of metals, ceramics, and semiconductors

- Sintering of powders and green bodies

- Thermal decomposition & pyrolysis, such as in carbonization and biochar production

- Battery material synthesis, including LFP, NMC precursors and solid electrolytes

- Semiconductor wafer processing research and development

Any heat treatment under inert, reducing, reactive, rough or high vacuum atmospheres at temperatures typically ranging up to 1750°C without pursuing other heating technologies

3. Vacuum Induction Heating Tube Furnaces for faster heating of ferromagnetic samples

Induction delivers fast, localized heating with minimal consumables by eliminating traditional heating elements, but requires a sample or susceptor that will induce heat in the electromagnetic field, generating ramp rates anywhere from 50°C to 150°C/min up to as high as 3000°C depending on the power supply, and rating the remaining materials in the system design, for the target temperature.

Where induction heating shines:

- Metal melting, tempering, sintering, annealing and alloy development

- Brazing soldering, and diffusion bonding under vacuum

- Rapid thermal processing RTP of conductive and coupled materials

- Degassing and purification of metals

- Advanced metallurgy & additive manufacturing feedstock development

4. RTF Rotary Tilting Tube Furnaces & Autofeed Rotary Kilns

Rotation and inducing tumbling ensure uniform heat exposure and mixing, ideal for powders and granular materials. Hoppers, augers, conveyors and collection tanks allow for continuous heat treatment, for R&D, pilot and production scale thermal processing.

Reasons to use Rotary Tube Furnaces:

- Catalyst activation and regeneration

- Battery powder processing and coating

- Calcination of ores and mineral samples

- Thermal treatment of granular materials

- Continuous pyrolysis and decomposition reactions

Powder Drying when paired with the proper cold trap and vacuum system

5. RTF Rotary Tilting Tube Furnaces & Autofeed Rotary Kilns

Orders-of-magnitude faster sintering from 10°C/min to 500°C/second using either a set of halogen lights up to 1200°C, or direct current up to 3000°C, ideal for ultra-fast densification, cutting edge ceramics, advanced and performance materials

High-Value Applications

- Advanced sintering, such as with graphite and ceramics, including zirconia, alumina and solid electrolytes

- Energy-efficient densification research

- Solid-state battery materials

- Functional ceramics for sensors and fuel cells

How does one select the best tube furnace?

On paper, many vacuum tube furnaces look interchangeable, but it is important to ask the correct questions during the system and standard procedures or experiment design process.

Furnaces may reach the same maximum temperature, but how quickly do we want to achieve target temperature? How large is our sample, and how important is uniformity? The most basic tube furnace will be 1-Zone, or have a single temperature control zone, but furnaces can be 2-Zone, 3-Zone, 6-Zone or however many areas can be controlled by a thermocouple or temperature measurement device, and set of heating elements, resistive or induction heating coil, set of halogen lights or direct current heating, depending on the furnace selected for the process.

They pull to similar ultimate vacuum levels… on paper, but that is just the rating of the furnace tube itself. What vacuum fittings, valves and pumping systems are connected to the flanges, and are we OK with monitoring this with a mechanical or digital vacuum gauge, or should we implement a repeatable, digital vacuum control system, tracking vacuum and pressure as closely as temperature?

They accept the same nominal tube diameters, but how many samples am I truly trying to load and effectively heat? How large a heating zone and payload do I need? What are my goals per batch, hour, day, week and year?

This surface-level similarity without selecting with intention, experience and asking the right questions is precisely why so many systems are mis-specified, and can fall below expectations, if not entirely fail to accomplish ultimate goals and requirements.

Engineers are trained to optimize for measurable limits, peak temperature, ultimate vacuum, maximum gas flow, but thermal processing success rarely hinges on specifications and maximum values listed on a website listing or piece of paper. It hinges on system and process design, stability, repeatability, compatibility, and reliability over time.

A vacuum system can achieve 10⁻⁵ Torr once but exposes your material to contamination that renders data useless or wears your pump away to consumable hardware due to a chemistry mismatch. A tube, flange or seal material that survives early runs but reacts with process gases months later can become yet another contamination source. Every wetted material matters.

These failures don’t announce themselves immediately. They appear gradually, quietly, in testing data and maintenance schedules… or unscheduled maintenances… and often after protocols have already been written around potentially flawed assumptions and unreliable data sets.

What makes a successful tube furnace system?

Top three considerations:

1. Selecting the best tube furnace, the core of your heat treatment process

After outlining what tube furnaces technologies are available to you, assess the form of your sample, what chemical and thermal challenges you may face and how best to address them for optimal thermal treatment.

Pre-heaters and Multi-Zone Furnaces can create temperature gradients along the same vacuum tube atmosphere, as well as gas mixers and plasma generators can be used for CVD and PECVD Plasma-Enhanced Chemical Vapor Deposition to deposit onto a substrate for coating and crystal growth applications. Sizing the tube heating zone, and thus working space and volume, will play into the decision making of tube outer and inner diameters, as well as number and length of heating zones.

When continuous processing of powder samples is the goal, Across International RTF-AF series AutoFeed Rotary Tube Furnaces have dual augers for vertical and horizontal sample feeding, a wide variety of sizes of vibratory hoppers and collection tanks equipped with site glasses to monitor contact surfaces, as well as options for baffled quartz and stainless steel tubes for increased capacity and inducing tumbling and uniform heat treatment of powders, as well as fittings for flow gas, vacuum measurement, pumping and control.

At its core, the components assembled into the furnace will determine the quality of performance. Across International selects leading industry partners for each important element in the furnace assembly, from Kanthal A1 Wire Heating Elements to Mitsubishi alumina ceramic, controlled by Eurotherm temperature controllers that offer data-logging, PC interface for remote control, monitoring, I/O communication and system integration.

2. Building the system: tube, flanges, seals, gas flow and vacuum Control

Depending on the design of your furnace, different tube materials will be available for your selection for endurance, chemical compatibility and thermal properties. Across International offers high purity quartz, alumina ceramic, 310S stainless steel and Hastelloy tubes. Please see maximum temperature of each below, and keep in mind that metallic tubes like Hastelloy and stainless steel will require water-cooled flanges, which can in general be advantageous for keeping flanges cooler, easier to handle, and preserving precious vacuum seals, particularly with heavier gas flow that will contribute to heat conductance.

|

Tube Material |

Maximum Temperature Rating (Direct Contact) |

|

310S Stainless Steel |

900°C |

|

Hastelloy |

1200°C |

|

Quartz |

1200°C under atmosphere, 1000°C under vacuum |

|

Alumina Ceramic |

1800°C |

Seal materials can vary from standard Silicone to Viton, Chemraz, Kalrez, PTFE, EPDM and other elastics and sealing materials depending on chemical compatibility and resistance requirements.

Sealing flanges are typically standard 304 stainless steel, but can be 316L or other alloys, PTFE-coated and made of a variety of materials again depending on what vapors they will be exposed to, as well as optimizing for functionality.

It is also important to keep in mind what vacuum fittings are built into the flanges, and the effective inner diameter exposing your process to the gas flow, which can be manually throttled or controlled with a digital MFC mass flow controller or gas mixing system, and the vacuum, which will perform similar in gas flow to a liquid pipe or hose; the wider the orifice, the longer and more circuitous the piping, will all ultimately play into the ultimate vacuum, gas flow and thus furnace system performance.

Vacuum pumping systems can range from standard hydrocarbon to synthetic PFPE or other oil sealed and lubricated systems, or oil-free technologies with different levels of chemical resistance. Rough vacuum can be accompanied by high vacuum diffusion “wet” pumps or turbomolecular “dry” pumps for deeper ultimate vacuum, as well as booster pumps for increasing pumping speed, and ensuring your vacuum system is designed to resist any volatiles that may be produced in your system, or incorporating a cold trapping system to capture those vapors before they make it to the pump, is critical for longevity and overall performance.

Finally, how are we measuring our vacuum pressure, and are we relying on the vacuum pump and seals to reach the same vacuum every day, or experimenting with a vacuum, mass flow, bleed controller or some combination thereof to optimize pumping speed, drying and heat treatment times for repeatable, unbeatable performance?

Across International offers all these tools, and expertise to help optimize depending on your goals, contact us to design the best system for your thermal process!

3. Options for Rapid Heating & Cooling when important

Air, gas and liquid quenching can be incorporated to rapidly cool samples and production batches when this is advantageous.

Sliding tube furnaces mounted on a track can slide the hot zone over and off samples in order to accomplish quick heating and cooling rates without risking damaging thermal insulation.

Rotary Tilting Tube Furnaces similarly allow for optimizing residence time and then removing your sample from the hot zone into a collection tank either at atmospheric temperature, or jacketed for thermodynamic temperature control if advantageous.

Induction and flash sintering systems can be rapidly turned on and off at will to produce very quick heat treatment cycles, which can be optimal for quick sample and batch processing.

Flow gas and even dropping the sample entirely in a liquid quenching bath, can be used for cooling depending on the use case.

Your partners in tubular temperature control

In addition to new systems, Across International offers temperature and vacuum calibration, spare parts, and is always happy to serve as a resource in the laboratory or at the plant!

Contact your account manager to ensure your heat treatment team has a tubular time

You may learn more about what Across International has to offer at:

888-988-0899

www.acrossinternational.com

We look forward to helping with the best thermal processing solution for your work!