Distillation is one of the commonly used operations in chemical processes. Through distillation, you can characterize materials by establishing a purity index and separating selected components from a complete matrix. You can choose from various distillation methods suitable for your industry, but short path distillation is the most popular technique.

If you want to know more about short path distillation, this infographic will discuss its procedure, utilization, advantages and disadvantages, and equipment requirements when carrying out the process.

What is Short Path Distillation?

Also known as fractional distillation, short path distillation is a process that separates and purifies materials from other compounds based on volatility differences through low-pressure evaporation. It uses a vacuum pump to lower atmospheric pressure, which lowers the boiling points of the compounds inside the distillation system. This process makes the distillation of heavier molecules quicker and more efficient than other methods.

The name of this technique describes the short distance – typically a few centimeters – that the materials being distilled travel once in the apparatus. Short path distillation’s application ranges from food, beverage, and pharmaceutical industries to petroleum refineries. One significant advantage of implementing short path distillation in your production process is its practical requirements.

Unlike conventional distillation techniques that need heavy-duty equipment, short path distillation is possible with limited equipment and production capacity. Specialty flasks, test tubes, beakers, and other small glassware are enough. These handy instruments will allow you to achieve high purity levels without taking up a large area of your workspace.

Suppose you’re on a tight budget and lack the necessary space to house large distillation equipment. In that case, short path distillation is the ideal method to employ without sacrificing product quality.

How Does Short Path Distillation Work?

Short path distillation enables extraction by capitalizing on the material’s melting point rather than incorporating a spent solvent that helps distillate the material.

The distillation process starts by placing the extraction material inside a feed vessel. Once set, the material goes into a flask, which is positioned in a heating mantle that gradually increases the temperature solution to preset boiling points. The continuous heat increase will trigger particular compartments of the mixture to evaporate.

Aside from heat, the setup also produces a vacuum within the flask, decreasing the system’s atmospheric pressure and the evaporation material’s boiling point. The result is a faster and more efficient distillation of heavier molecules.

Additionally, the vacuum expedites evaporation by drawing vapors into the fractionating tube, where the mixed vapors cool, condense, and re-vaporize to further separate the solution.

Each cycle of condensation and vaporization then refines the material. And because the fractionating mechanism is close to the heated flask, the extract only needs to travel a short distance to reduce wasted distillate within the apparatus.

After the material passes through the fractionating tube, it enters the condensing line, turning the vapor back into a liquid. Then, each fraction will go to separate flasks according to its weight. You could run an extract through short distillation multiple times to separate and refine the product according to your preference.

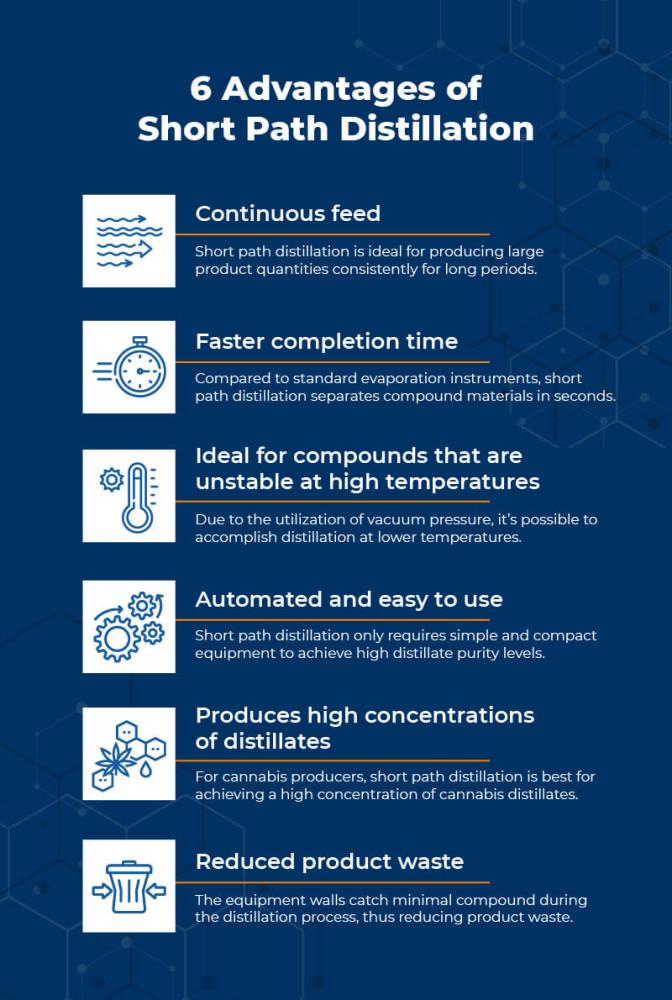

6 Advantages of Short Path Distillation

You can benefit from making the switch to short path distillation, as this method can lead to a more seamless production cycle. Here are specific advantages to utilizing short path distillation.

1. Continuous feed

The continuous feed functionality of short path distillation is a valuable feature not many other distillation methods can offer. Its highly accurate evaporation system needs fewer instances of high temperature to extract the same volume of a product. As a result, you can achieve greater production scalability, which isn’t typically possible with batch mode stills.

2. Faster completion time

Short path distillation is more advantageous than other methods like simple distillation. By utilizing short path distillation, you can achieve separation in seconds without compromising product quality thanks to its implementation of vacuum pressure, making it ideal for industries with time-sensitive materials and production cycles.

For comparison, simple distillation is faster and needs less energy when separating liquids than fractional distillation. However, its main drawback is that simple distillation is less efficient and limited to mixtures containing only one volatile component.

3. Ideal for compounds that are unstable at high temperatures

Some compounds need high temperatures for effective separation. However, exposure to higher temperatures may cause some elements to become unstable. Short path distillation mitigates this risk by reducing a compound’s boiling point through vacuum pressure.

4. Automated and easy to use

Short path distillation is easy to use, unlike most conventional distillation strategies requiring bulky and intricate machinery. Simple and compact equipment is enough for short path distillation to produce high-quality distillate levels.

In addition, you can find short path distillation equipment with an automation feature capable of continuous feeding, which is crucial to high quantity distillate production while maintaining consistency, purity, and potency. This ability to automate processes contributes to overall volume increase and scalability.

5. Produces high concentrations of distillates

If you’re looking to produce a purified cannabidiol (CBD) product, then implementing short path distillation in your processes will allow you to do so. A short path distillation system separates CBD and tetrahydrocannabinol (THC), resulting in 99% pure cannabis distillates.

6. Reduced product waste

Fractional distillation minimizes compounds lost on the fringes of the apparatus. That is thanks to the short path the compounds have to travel from one instrument to another – from the heated flask to the condensation tube – which leads to less product wastage involving expensive compounds that require distillation.

5 Industries That Utilize Short Path Distillation

The distillation method’s ability to produce high-quality concentrates quickly is one of the main reasons some industries with intricate processes choose the system. Here are some sectors that utilize short path distillation.

1. Chemistry labs

Chemistry labs primarily use short path distillation for chemical purification and separating compounds to obtain specific components by subjecting mixtures to high-vacuum conditions, resulting in reduced pressure.

2. Perfume labs

Distillation remains the primary technique in traditional perfume production. Extraction through distillation has been around for centuries, as producers would use distillation to treat specific flower petals, bark, seeds, leaves, and roots.

Nowadays, perfume labs utilize short path distillation for molecular separation. Since fractional distillation can extract a specific molecule from a natural ingredient, perfume labs turn to this method to qualify perfume molecules as natural and even allow the fragrance to be organically certified.

3. Cannabidiol labs

Cannabidiol labs often choose short path distillation as it presents a cost-efficient method of separating cannabinoids, terpenoids, contaminants, and flavoring chemicals. Short path distillation does not require the addition of solvents to activate the distillation process.

Additionally, the method’s capability of producing high evaporation rates contributes to increased levels of distillate concentrate for cannabis producers.

Using short path distillation, cannabis labs can purify cannabis components and process cannabis plant material into distillates independently, helping brands create a range of CBL products.

4. Petroleum refineries

Petroleum producers separate hydrocarbon chains to refine crude oil into valuable petroleum products using short path distillation to divide, split, and even combine these chains.

5. Petrochemical and chemical plants

Extracting petrochemicals involves significant energy consumption and a distillation phase to separate hydrocarbons from fossil fuels, which are the primary source of petrochemicals like natural gas and crude oil. The extracted hydrocarbons would then be sent to chemical plants to turn into valuable chemicals known as a feedstock.

A Long List of Benefits for Short Path Distillation

Short path distillation is ideal for many industries. The method provides many benefits, from faster production cycles and reduced product wastage to high distillate concentrates. Short path distillation is efficient if you’re looking for a quick, inexpensive way of production without sacrificing quality.

Across International is your best option if you’re looking for a manufacturer that offers high-quality material processing equipment. An industry leader in manufacturing laboratory, heat treatment, and material processing equipment, Across International aims to empower organizations in advancing science through innovative and high-quality equipment.

Our products are built using only the best materials and years of research and development to ensure that they’ll give you the level of performance and efficiency your lab needs. Across International carries short path distillation kits in multiple sizes and configurations, so you can surely find one that suits your application, from process chemistry to essential oil and cannabis distillation.

Request a quote for Across International’s short path distillation kit for labs today.