We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

All About Batteries: Research, Statistics, Manufacturing

Battery research and development projects have grown exponentially in the last decade mainly because many industries are transitioning away from fossil fuel dependence to slow the effects of climate change. With energy storage holding the key to a renewable-energy-fueled world, battery manufacturing will only continue to grow in the following years.

If you’re curious to learn more about the industry, this infographic will explore statistics, facts, and trends regarding battery research and manufacturing.

Battery Market General Statistics

Over the next decade, the U.S. energy storage market could grow to as much as $426 billion, according to a UBS projection.

As renewable energy resources become more inexpensive and produce less environmental damage, entire ecosystems will grow to support a new battery technology. Its effects and benefits will significantly impact society, helping to usher in renewable resources with a major focus on wind and solar energy.

Lithium-ion battery prices have decreased 20% to 50% over the last few years.

With the consolidation of the battery industry, competition within the niche will only continue to grow. Asian countries such as South Korea and China benefit from price drops and quality improvement as they look to gain traction in the global battery market.

The decrease in lithium-ion battery prices will prompt major battery manufacturers from the U.S. and Europe to delegate production to regions with lower costs.

An increase in lithium-ion battery production drives down prices, making electric vehicles commercially viable cost- and performance-wise.

Lithium-ion batteries are currently the most popular battery storage option worldwide, holding over 90% of the global grid battery market. This significant increase in popularity has benefited the electric vehicle industry. Not only did lithium-ion batteries make electric cars profitable but they also paved the way for a future without fossil fuel dependence.

Batteries are crucial in energy transition.

As society turns to more environmentally friendly alternatives like emission-free electrification, lithium-ion batteries – which are a vital energy storage tool – are in a prime position to facilitate the energy transition.

Cumulative demand for lithium-ion battery in energy storage and electric vehicle applications significantly increased from a mere 0.5 gigawatt-hours in 2010 to 526 gigawatt-hours in 2020. In addition, demand for lithium-ion batteries will continue to grow, as experts project a 17-fold increase in demand by 2030.

From a market size worth $108.4 billion in 2019, the global battery industry is expected to have a 14.9% compound annual growth from 2020 to 2027.

The global battery market’s compound annual growth is due to continuous technological advancements and higher demand for portable electronics. Items such as smartphones, LCDs, and wearable devices – like fitness bands – play a big part in boosting market growth.

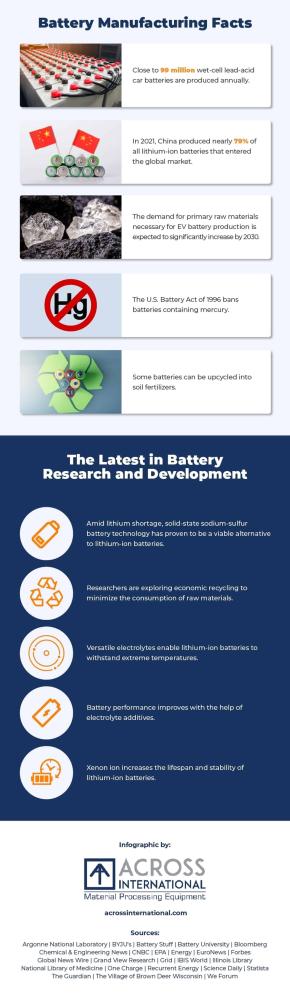

Battery Manufacturing Facts

Close to 99 million wet-cell lead-acid car batteries are produced annually.

Batteries are convenient portable energy sources that people utilize daily to power their appliances, electronics, and tools. However, some may not be aware of the importance of batteries in more critical situations. During power outages, phones feature lead-acid batteries that allow them to continue functioning.

More importantly, batteries provide reserve energy to operate commuter trains, manage power fluctuations, and power essential functions, including military and medical services. This wide dependence on batteries can inevitably lead to an overabundance of incorrectly disposed battery waste, which can harm the environment.

One way to reduce battery waste is to recycle. Batteries made from zinc-carbon and alkaline are safe to send to a battery recycler. Using rechargeable or dry-cell batteries is also an environmentally friendly alternative to single-use batteries.

In 2021, China produced about 79% of all lithium-ion batteries that entered the global market, dominating the world’s lithium-ion manufacturing market that year.

China’s position as the number one producer of lithium-ion batteries dates back decades ago. BYD Auto Co., a Chinese mobile phone battery maker, started the country’s electronic vehicle (EV) market boom when it bought Tsinchuan Automobile in 2003. BYD then produced EVs with batteries from their vertically integrated domestic supply chain.

The Chinese government fully supports expanding the lithium-ion battery manufacturing market within the country, allocating $214 million in electric vehicle research funding, primarily for battery technologies.

Demand for primary raw materials necessary for battery production is expected to significantly increase by 2030.

With electric-powered vehicles gaining popularity, the industry is expected to consume more raw materials for battery production. Experts project that lithium-ion batteries will be the standard solution in powering electric cars in the next 10 years, requiring chemical compounds like cobalt, graphite, lithium, nickel, and manganese to create.

Fortunately, there are enough raw materials, with the current total deposit exceeding the demand projection. However, experts believe there are still obstacles to overcome, including individual raw material price increases and the time it takes to mine each resource.

Lithium takes about 12 to 18 months to extract and process before they can be used for battery production. This timeframe is the main cause of the global lithium shortage, as industries simply cannot mine the metal fast enough to meet the soaring demand.

The Mercury-Containing and Rechargeable Battery Management Act of 1996 phases out batteries containing mercury.

On May 13, 1996, the U.S. passed The Mercury-Containing and Rechargeable Battery Management Act. This prohibits the use of batteries that contain mercury. Lawmakers passed the bill to provide cost-effective and efficient collection, battery recycling, and proper disposal of used nickel cadmium, small, sealed lead-acid, and other forms of regulated batteries.

Certain battery ingredients can act as soil fertilizers.

Batteries that contain harmful materials, like mercury, have a terrible reputation when it comes to environmental issues. However, a little-known fact about battery ingredients such as manganese and zinc is that they can help with soil fertility.

When correctly disposed of, manganese and zinc break down into salt-like substances. The soil then absorbs these salts as micronutrients, increasing the effectiveness of soil fertilization.

The Latest in Battery Research and Development

Researchers are looking for alternatives to lithium-based battery technology due to its worldwide shortage.

The chemical element lithium possesses high energy capacity and density, which supports grid-level storage when combined with renewable energy sources. Due to these advantages, lithium-ion batteries remain the preferred energy source to power EVs.

However, lithium carbonate prices have increased to an all-time high due to the worldwide shortage, leading researchers to look for alternatives. There are proposals to use ambient temperature solid-state sodium-sulfur battery technology as an adequate alternative to lithium-ion batteries.

Researchers say that for this technology to replicate the results of lithium-ion batteries, it must be easily fabricated, have excellent chemical stability, be mechanically stable, and reduce costs. Unfortunately, no single sodium solid electrolyte has achieved all four requirements simultaneously.While researchers have yet to perfect the new energy source, it provides a solid foundation for developing safe, energy-dense, sustainable, and low-cost solid-state sodium batteries.

Researchers are exploring methods for economic battery recycling.

Cathode materials sink quickly, making it more challenging to separate their materials. But, researchers from the Michigan Technological University (MTU) have developed a method that separates individual cathode materials by incorporating a process called froth flotation. Primarily used by the mining industry, froth flotation purifies and separates ores.

With the help of froth flotation, researchers could separate cathode materials and made another discovery. The separated cathode materials boasted high electrochemical performance and purity levels of up to 95% or higher.

The discovery is important because it helps decrease energy-intensive processing methods and the unnecessary extraction of valuable materials for direct recycling. This new method makes recovery, regeneration, and reuse of battery parts possible without breaking down the battery’s chemical structure.

Versatile electrolytes enable lithium-ion batteries to perform well in frigid and hot temperatures.

University of California San Diego engineers produced lithium-ion batteries that sustain their power while subjected to frigid and scorching hot temperatures. The engineers accomplished this feat by creating a versatile electrolyte amid a wide range of temperature changes and which is compatible with high-energy cathodes and anodes.

These batteries enable EVs to travel farther in cold temperatures on a single charge and eliminate the need for cooling devices that prevent the engine from overheating in hot temperatures.

Upon further testing, these batteries retained 87.5% and 115.9% energy capacity at -40°C and 50°C, meaning they can withstand multiple discharge and charge cycles before they become unusable.

Electrolyte additive improves battery performance at high voltages.

A Department of Energy (DOE) chemist-led research team discovered an electrolyte additive that enables stable high-voltage cycling of nickel-rich layered cathodes. The team’s discovery could be the catalyst in improving lithium-ion batteries’ energy density in powering EVs.

Nickel-rich layered cathodes degrade upon exposure to high voltages, and these electrolyte additives provide a possible remedy to this problem. A researcher from Stony Brook University stumbled upon this discovery during an attempt to utilize the additive for high voltage cycling at room temperature.

In pushing the voltage to 4.8 volts, the additive strengthens the cathode to render excellent battery cycling performance. The additive’s capability to stop transition metal dissolution provides a blueprint for continuous improvement of battery cycling performance.

Researchers have successfully increased the stability and lifespan of lithium-ion batteries.

A research team from the University of Surrey identified a common problem for lithium-ion batteries during transit. During the transport of batteries, their casings would crack due to extreme temperatures and stressful situations.

Fortunately, the research found that injecting Xenon ions into ceramic oxide material creates a solid-state electrolyte.

Solid-state batteries injected with Xenon ions boasted a 30-time lifespan improvement compared to regular non-injected batteries. Researchers from the university hope the breakthrough boosts the scientific development of high-energy and sustainable batteries.

Betting on Batteries

The demand for batteries has grown exponentially, and industry experts predict more growth and opportunities for the battery market in the coming years. As people look to transition to more eco-friendly alternatives like solar or wind energy, batteries will play a valuable role in society’s shift to renewable energy resources.

If you’re looking for a reliable manufacturer of material processing, heat treatment, and laboratory equipment, look no further than Across International. Our company’s mission is to assist those who advance science by offering innovative and high-quality lab equipment.

Request a quote on your lab equipment today or visit the Across International blog for more information about the latest in industrial manufacturing.