The reactor is a vital part of any chemical industry also called as the heart of the chemical process where chemical reactions in conducted. Product is the result of the process of raw material hence chemical reactors are important equipment in any process.

In any type of industries such as the chemical industry, polymer industry, Dyes and pigment industries, color industries, pharmaceutical industries, and many more reactor plays an important role in a chemical reaction.

There are several types of reactors that are being used based on the types of reaction, and raw material properties hence there are selection criteria for selecting the reactors in the industry. Today in this post, we are going to learn about different types of reactors being used in the chemical industry with examples.

What is Chemical Reactor

A reactor is a process vessel design to add chemicals and conduct chemical reactions. The chemical reactor consists of different parts Chemical reactors are designed to give maximum yield in a chemical reaction. Different types of reactions are being carried out in chemical reactors.

Types of Chemical Reactors

There are several types of reactors that are being used in Chemical industry. Selection criteria, i.e. when to use which type of reactor will be discussed in the later part of the article. The basic types of reactors are as follows

Batch Reactor

Continuous stirred tank reactor

Batch Reactor

A batch reactor is the simplest type of reactor that consists of agitator and had a provision to apply utilities to heat ot cool the reaction mass. This is a closed system in which there is no flow of material entering or exiting the system. In the batch reactor, raw materials are charged into the reactor and allow to get agitation. Jackets are provided to the batch reactors where we can apply utilities to heat or cool the reaction mass according to the process requirement. These are mostly used in the pharmaceutical industry and also prepare solution i.e dosing chemicals etc. Batch reactors are used for chemical preparation, fermentation, crystallization and etc.

Batch Reactor Application – Batch reactors are used to prepare chemicals for dosing in the reaction. In caustic chlorine industry, batch of sodium sulfite is prepared that is used to dose in brine to remove free chlorine is dichlorination outlet

Continuous stirred tank reactor

Continuous stirred tank reactor in another type of reactor also known as back mix reactor, mixed flow reactor (MFR), or continuous-flow stirred-tank reactor (CFSTR) is widely used in the chemical industry and had various applications. CSTR reactors are batch reactors with open systems and have an impeller equipped with it to provide agitation for proper mixing or reactor content. these reactors allow adding continuous raw material into the reactor and continuous removal of product. CSTR reactor is considered an idealized agitated tank reactor and use to model operation variables required to achieve a specified output.

CSTR Application – CSTR reactors are used in chemical industries, especially in continuous plant

Pharmaceutical Classification

In life-science applications, reactor types are based on the material of construction and process of interest specifically;

Stainless Steel Reactors (SSR)

Glass Lined Reactors (GLR)

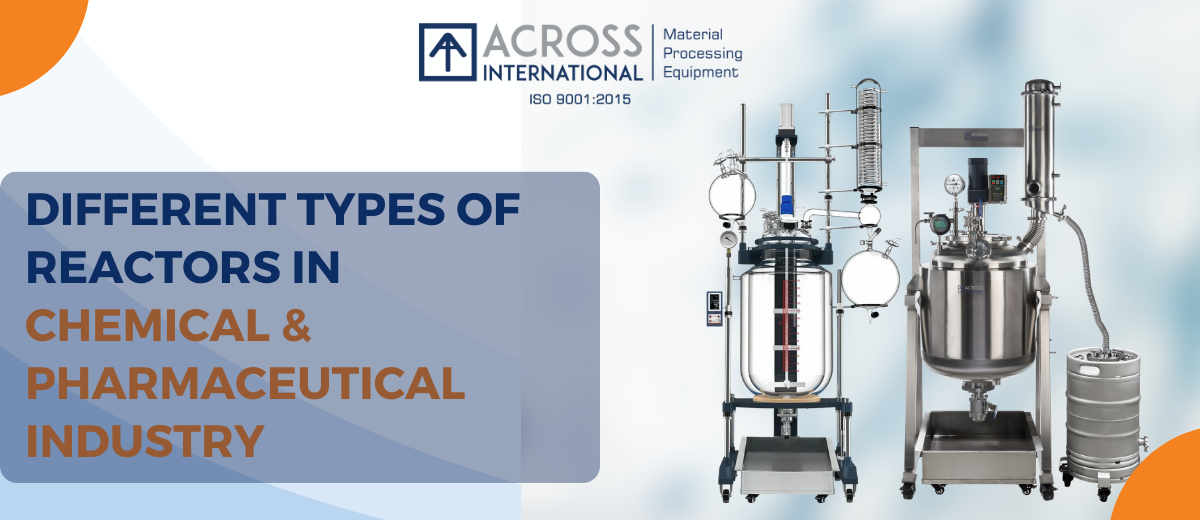

Across International Lab Glass Reactor

Glass Reactors are extremely versatile in their applications and crucial to sectors such as pharmaceutical production, research and process chemistry, botanical extraction, and purification, as well as various food, and industrial, processes. Across International offers reaction vessels in both glass and stainless steel, ranging from 10 liters to 200 liters.

Across International Glass Reactors combine robust construction, precise temperature control, and safety features to meet the demands of the pharmaceutical industry. Whether you need a reactor for research and development or large-scale production, our glass reactors provide the reliability and performance you require. Contact us today to explore how our glass reactors can enhance your pharmaceutical processes.

Stainless Steel Reactors are extremely versatile in their applications and crucial to sectors such as research and process chemistry, botanical extraction and purification, pharmaceutical production, aerospace and semiconductor, material processing and more. Across International offers 316L stainless steel reactors in 100, 200, and 300L models, as well as in 100 and 200L filter reactor configurations.

Now that you know just about anything you ought to with regard to the glass reactors used in the pharmaceutical industry, we now expect you to move ahead to now appreciate it better.

UL/CSA Certification: Our glass reactors come with the option of UL/CSA certification. This certification demonstrates that our reactors meet rigorous safety and performance standards, providing you with confidence in the reliability and quality of our products.

Contact us today to explore the possibilities of our glass and stainless-steel reactors and revolutionize your industrial processes. This can only mean you find the best one and devote it to your everyday pharmaceutical applications.