We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

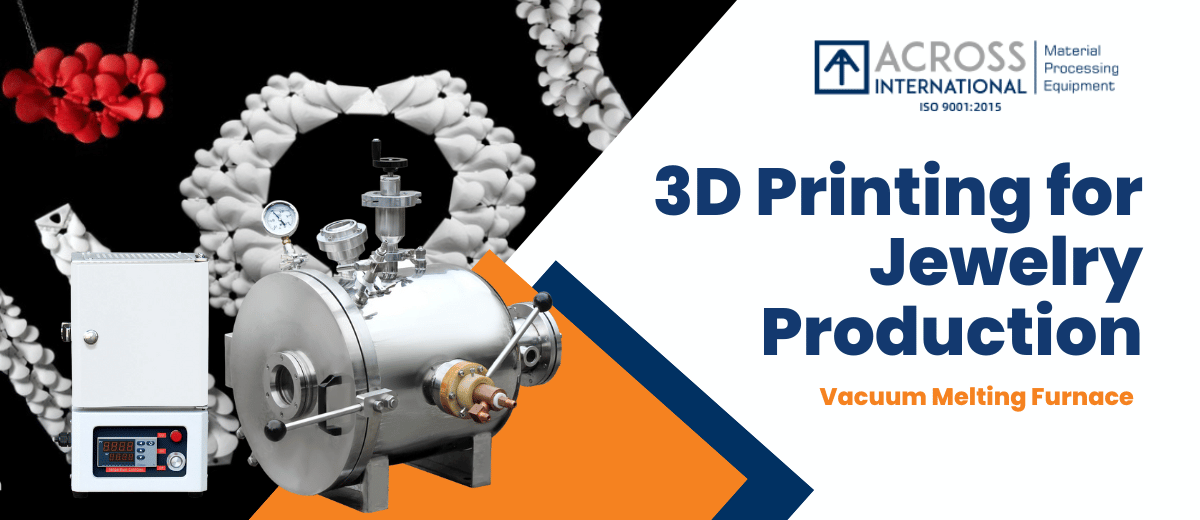

Vacuum Melting Furnace for 3D Printing Technology

3D printing is a revolutionary technology that is transforming many industries, including jewelry production. 3D printers can be used to create complex and intricate jewelry designs that would be difficult or impossible to produce using traditional methods.

There are two main types of 3D printing used in jewelry production: direct metal printing and indirect printing.

Direct metal printing uses lasers to fuse metal powder particles together to create solid metal objects. This process is used to create high-quality jewelry in precious metals such as gold, silver, and platinum. However, direct metal printing is expensive and requires specialized equipment.

Indirect printing uses 3D printers to create casting patterns or molds, which are then used to cast jewelry in metal. This process is more affordable and accessible than direct metal printing, and it can be used to create jewelry in a wider range of materials, including plastics, resins, and waxes.

Vacuum furnaces are very useful for 3D printing, as they can provide the high temperatures and precise control needed to produce high-quality parts. Vacuum furnaces are also used to debind and sinter binder jet 3D printed parts.

Here are some of the benefits of using a vacuum furnace for 3D printing:

High temperature uniformity: Vacuum furnaces can provide high temperature uniformity throughout the furnace chamber, which is essential for producing high-quality 3D printed parts.

Reduced oxidation and contamination: The vacuum environment prevents oxidation and contamination of the materials being processed, which can lead to improved surface finish and mechanical properties.

Precise control: Vacuum furnaces offer precise control over the heating and cooling process, which is important for producing parts with the desired properties.

Versatile: Vacuum furnaces can be used to process a variety of materials, including metals, polymers, and ceramics.

Vacuum furnaces are a valuable tool for 3D printing, and they are used by a variety of industries, including aerospace, automotive, and medical.

Here are some examples of how vacuum furnaces are used in 3D printing:

Heat treating metal parts: Vacuum furnaces are used to heat treat metal parts to improve their strength, hardness, and ductility.

Annealing metal parts: Vacuum furnaces are used to anneal metal parts to relieve stress and improve their machinability.

Sintering binder jet 3D printed parts: Vacuum furnaces are used to debind and sinter binder jet 3D printed parts to produce solid metal parts.

Choosing a vacuum melting furnace for jewelry 3D printing, it is important to consider the following factors:

Capacity: The capacity of the furnace will determine how much metal you can melt at one time. If you are planning on melting large batches of metal, you will need a furnace with a large capacity.

Temperature range: The temperature range of the furnace will determine the types of metals you can melt. If you are planning on melting high-purity metals, you will need a furnace with a high temperature range.

Accuracy: The accuracy of the furnace will determine how precisely you can control the melting temperature. This is important for jewelry 3D printing, as you need to be able to melt the metal at the correct temperature to produce high-quality parts.

Price: Vacuum melting furnaces can be expensive, so it is important to factor price into your decision.

3D printing is a rapidly evolving technology, and new applications for 3D printing in jewelry production are being developed all the time. It is an exciting time to be involved in the jewelry industry.

Vacuum furnaces are an essential tool for many 3D printing applications. They offer several advantages, including high temperature uniformity, reduced oxidation and contamination, precise control, and versatility.

If you are serious about 3D printing, Across International vacuum furnace customized best vacuum melting furnace as per the customer needs. It will allow you to produce high-quality parts that would not be possible with other methods. Contact us for more technical information.