A rotary evaporator is a critical tool used in various industries for solvent removal. Its importance lies in its ability to efficiently evaporate solvents from liquid samples, enabling concentration and purification. Widely utilized in pharmaceutical research, chemical synthesis, and other fields, rotary evaporators play a crucial role in enhancing productivity and ensuring the integrity of the final product.

Basic Principles of Rotary Evaporation

The process of rotary evaporation involves several key principles that contribute to its effectiveness.

Evaporation: The solvent transitions from a liquid to a vapor phase as the rotating flask is heated, facilitating evaporation.

Condensation: The solvent vapor rises and enters the condenser, where it is cooled, causing it to condense back into a liquid state.

Vacuum and temperature control: The application of vacuum reduces the pressure, lowering the boiling point of the solvent for evaporation at lower temperatures. Precise temperature control ensures optimal evaporation without compromising heat-sensitive samples.

Solvent recovery: The condensed solvent can be collected and reused, minimizing waste and improving cost-effectiveness.

Guide for Setting up Rotray Evaporators in Your Labortary

Initital Setup

* Select an appropriate flask size based on the volume of the liquid sample to be evaporated. A larger flask allows for more efficient evaporation.

* Attach the flask to the rotary evaporator's motorized lift and ensure a secure connection.

* Connect the flask to the condenser, ensuring proper alignment.

* Set up the water bath and ensure it is filled with an appropriate heating medium, such as water or oil.

Parameter Optimization:

* Determine the optimal rotation speed for the flask. A moderate speed is usually sufficient for efficient evaporation without splashing or excessive foaming.

* Adjust the temperature of the water bath to achieve the desired boiling point of the solvent, considering its vapor pressure and thermal stability.

* Apply vacuum to the system to lower the pressure and reduce the boiling point of the solvent, enabling evaporation at lower temperatures.

Evaporation:

* Begin rotating the flask and gradually increase the temperature of the water bath.

* As the solvent evaporates, observe the liquid level in the flask and maintain it within the appropriate range.

* Monitor the evaporation process, ensuring a steady and controlled removal of the solvent.

Condensation:

* The solvent vapor rises from the flask and enters the condenser.

* The condenser, cooled by circulating water or a refrigeration system, causes the vapor to condense back into a liquid state.

* The condensed solvent collects in a separate container for further analysis or reuse.

Final Product Collection:

* Once the desired amount of solvent has been evaporated and collected, stop the rotation of the flask.

* Safely disconnect the flask from the rotary evaporator and handle it according to the appropriate safety procedures.

* Transfer the collected solvent to a suitable container, ensuring proper labeling and storage.

By following this step-by-step guide and considering the important parameters, scientists and researchers can effectively and safely conduct rotary evaporation, enabling efficient solvent removal and concentration in various industries.

Applications of Rotary Evaporators

Rotary evaporators find applications in a wide range of industries, enabling efficient solvent removal and concentration.

Pharmaceutical research and production: They aid in drug discovery, natural product extraction, and API purification.

Chemical industry: Used for solvent recovery, concentration, and compound synthesis.

Food and beverage industry: Employed in flavor extraction, extract concentration, and aroma preservation.

Environmental analysis: Used in the concentration and extraction of compounds from water, soil, and air samples.

Essential oil extraction: Facilitate the removal of solvents from plant and herb extracts for pure and concentrated essential oils.

Research and development: Assist in sample preparation, purification, and compound concentration for analysis.

Cosmetics and fragrance industry: Used for the extraction and concentration of fragrance compounds and essential oils.

Rotary evaporators enable efficient solvent removal and concentration across these diverse industries, contributing to improved processes and high-quality end products.

Safety Considerations

Proper ventilation and personal protective equipment (PPE) are essential for safe rotary evaporator use. Ventilate the work area or use a fume hood to prevent the accumulation of harmful vapors. Wear appropriate PPE like lab coats, safety goggles, and gloves to protect against chemical splashes and hot surfaces.

Handle hazardous solvents carefully by following safety data sheets (SDS) and proper handling, storage, and disposal procedures. Use heat-resistant gloves or tongs when dealing with heated components. Employ vacuum traps and pressure release valves for safe operation under vacuum conditions.

Ensure electrical safety by following guidelines, proper grounding, and regular inspection of cords and connections. Regular maintenance, including inspections of the condenser, flask, and seals, is crucial to prevent accidents or leaks.

Prioritizing these safety measures creates a secure working environment when using rotary evaporators, protecting against potential hazards and ensuring the well-being of all involved.

Rotary evaporators are vital tools in various industries, enabling efficient solvent removal and concentration. By understanding the basic principles and following a step-by-step guide, researchers can effectively utilize rotary evaporators for a wide range of applications.

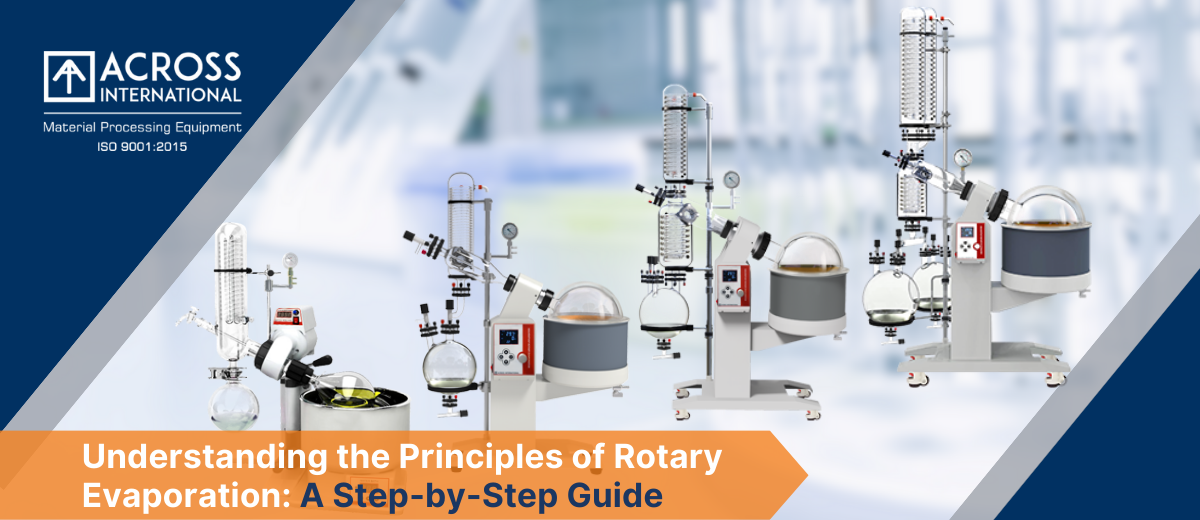

Discover the excellence of Across International's rotary evaporators. Our rotovaps are certified by UL, CSA, and CE, guaranteeing safety and compliance. With advanced vacuum controllers and the option to customize with larger ancillaries, you can optimize your package for optimal performance. Choose from our extensive range of rotary evaporator models, ranging from 2 liters to 50 liters, to suit your specific process requirements. Contact us for upgrading your lab with Across International's rotovaps and secure yours today!