We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Industry Furnaces: Leading the Way in Future Battery Technology

Industrial Furnaces help for Battery Research & Build

Industrial furnaces can play an important role in battery research and build by providing a controlled environment for the synthesis, processing, and testing of battery materials. Here are a few ways in which industrial furnaces can assist in battery research and build:

Synthesis of Battery Materials:

Industrial furnaces can be used to synthesize battery materials such as cathodes, anodes, electrolytes, and solid-state electrolytes. These furnaces can provide high-temperature environments required for the synthesis of complex materials and can also provide precise temperature control to ensure the quality of the synthesized material.

Heat treatment and annealing:

Controlled atmosphere furnaces are used to heat treat and anneal battery materials, such as electrodes and electrolytes, at high temperatures in a controlled environment. This allows for the removal of impurities and the creation of a uniform and crystalline structure, which is essential for optimal battery performance.

Controlled atmosphere furnaces can be used to perform heat treatment on battery materials to improve their properties. For example, heat treatment of lithium-ion battery electrodes can improve their capacity, cycle life, and safety. Furnaces can provide precise temperature and atmosphere control during the heat treatment process, which is crucial for obtaining the desired material properties.

Testing of battery materials:

Controlled atmosphere furnaces can also be used to test the performance of battery materials under different atmospheric conditions. By controlling the atmosphere, researchers can simulate the conditions that a battery would experience during use, allowing them to better understand how the materials will perform in real-world applications.

Overall, controlled atmosphere furnaces are a crucial tool in battery research, enabling the creation and manipulation of the chemical environment in which battery materials are synthesized and processed. By controlling the atmosphere, researchers can optimize the properties of battery materials and develop new and advanced battery chemistries that are more efficient, durable, and sustainable.

Overall, industrial furnaces can provide a highly controlled environment for battery research and build, enabling the synthesis, processing, and testing of battery materials with greater precision and accuracy.

Powering the Future with New Battery Technology

Lithium batteries are the most popular on the market today. These are used in multiple applications, such as mobile devices, electric vehicles, and more. However, lithium supply and extraction can’t keep pace with the growing demand. And while there have been new discoveries, the continuous developments in the battery market are a must to facilitate the world’s shift to renewable energy sources.

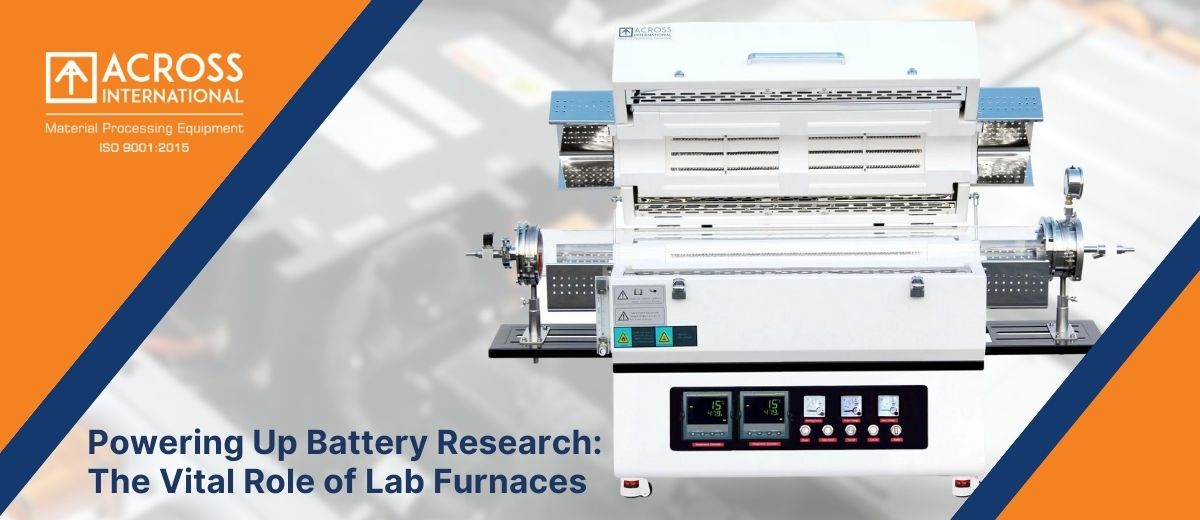

Having the best lab equipment is essential in advancing battery technology. Tube Furnaces or Controlled Atmosphere Furnaces in particular, are heavily used in various stages of battery production. Heat Treatment is indispensable in the production of lithium-ion batteries because it ensures the integrity of the cell structure.

At Across International, we work with researchers and manufacturers around the world. Our experts can provide advice and expertise on the furnaces and thermal treatments that make the biggest impact on the battery manufacturing /research industry. We’re always here to help, so please get in touch today.

If you’re looking for a Furnace for battery production, look no further than Across International. Across International carries laboratory furnaces, vacuum drying ovens, and other lab equipment to help with your battery research and manufacturing. We design versatile vacuum furnaces that can be integrated into production lines and research facilities across industries.

Request a quote today on your lab equipment or visit the Across International website to know the latest on industrial manufacturing equipment.