We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Induction Heating Coils: Efficient and Powerful, Coil Design

Induction Heating Coils: Efficient and Powerful, Coil Design

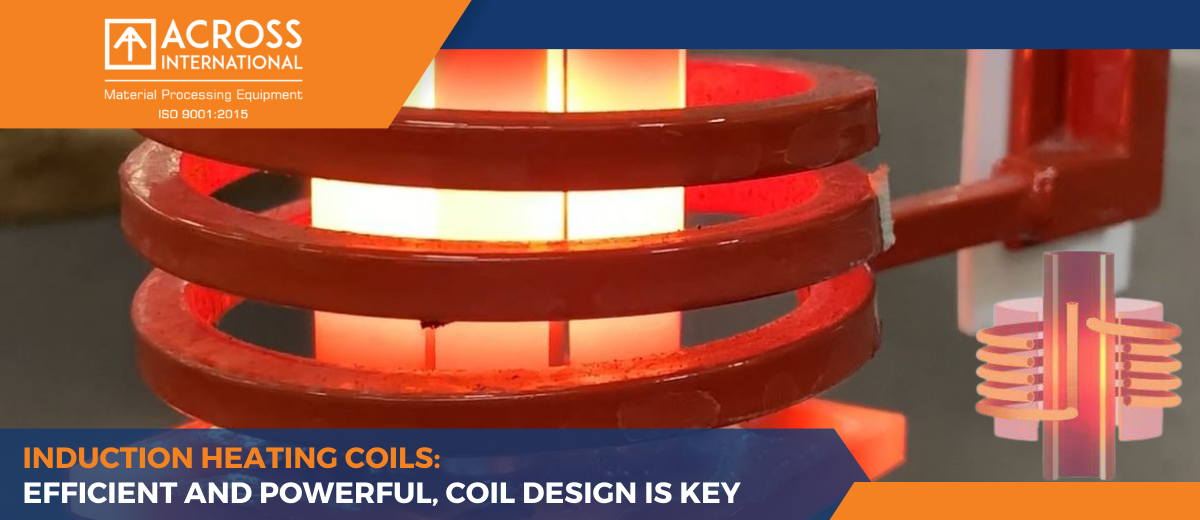

The way we heat different materials has been transformed by the commonly utilized industrial technology known as induction heating. The layout of the induction heating coil is crucial to this procedure. The design of the induction heating coil is crucial in the industrial sector, where efficacy, productivity, and cost-effectiveness are crucial factors. What are the fundamentals of induction coil design and suggestions for making it more effective for your part and procedure?

How do Induction Heating Coils work and why it is important?

When an alternating current flows through the coil and creates a fluctuating magnetic field, an electrical current is induced in the conductive material. The material heats up quickly and efficiently as a result of the current because of its natural electrical resistance.

Electronics, aerospace, and the automobile industry all often employ induction heating. For instance, induction heating is used in the production of automobiles to heat-treat engine parts like crankshafts and connecting rods to improve their tensile strength and endurance. Turbine blades are fabricated and repaired using induction heating in the aerospace sector because they need precision heating to resist high temperatures and strains.

The design of the induction heating coil is crucial for optimal heating efficiency and quality. The geometry of the coil, including its size and form, must be customized for the particular material and component being heated. To get the correct heating outcomes, the frequency, power, and duration of the electrical current must also be precisely adjusted. Induction heating is a potent and effective technique for heating conductive materials, and ideal results need precise coil design.

Designing Induction Heating Coils: Rules, Principles, and Considerations

In order to obtain the best results for your industrial application, the design of induction heating coils is a challenging procedure that calls for careful consideration of many different elements. There are five fundamental principles to remember in order to maximize your coil design: choosing the proper material, designing the coil to meet your demands specifically, maximizing inductance, and guaranteeing efficient cooling.

Size Matters: For effective heating, the coil's size is essential. An improperly sized or sized coil can result in inefficiencies and subpar performance. The size, shape, and material of your item, as well as the power output of your induction heating equipment, must all be taken into consideration when sizing your coil.

Material Selection: The coil's performance and durability may be impacted by its material. Copper, aluminum, and steel are common coil materials, and each has certain benefits and qualities. It's crucial to pick a material that works with your application, can endure the heat from the heating process, and can withstand wear.

Coil Shape: Your heating process' effectiveness and efficiency may be impacted by the coil's shape. To provide optimal heating, various coil forms, such as cylindrical, flat, or bespoke shapes, can be tailored for a certain component or material.

Inductance: The effectiveness of the heating process is significantly impacted by inductance, a key consideration in coil design. Accurately calculating your coil's inductance and optimizing it for your particular application are crucial.

Cooling: For your coil to last a long time and to avoid overheating, effective cooling is essential. Depending on their size, shape, and power output, your coil and heating equipment may employ one of various cooling approaches, such as air, water, or oil.

By considering these five basics in your induction heating coil design, you can optimize your process and achieve the best results for your manufacturing application. However, it's important to work with an experienced manufacturer or engineer who can evaluate your specific requirements and tailor your coil design accordingly.

A strong and effective industrial technique, induction heating depends on the induction heating coil's construction. Manufacturers are able to optimize their heating process and get the best results for their particular application by knowing the fundamentals of induction heating coil design, including size, material selection, coil shape, inductance, and cooling. To guarantee that the coil is customized to your unique specifications, it's crucial to engage with a manufacturer or engineer with experience in creating induction heating coils. Do not hesitate to get in touch with us for assistance at any point throughout the design of induction heating coils. We also offer free lab testing, from idea to final components.