We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

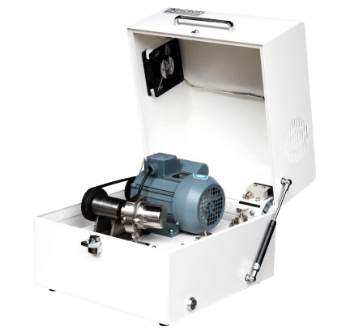

Choosing Right Laboratory Ball Mills for Powder Milling Application

Planetary ball mills and roller jar mills are both used to grind and mix materials, but they have different strengths and weaknesses. There are various considerations when deciding between planetary ball mills and roller jar mills

Final particle size: The final particle size of the sample after milling is the most important element. Planetary ball mills can achieve much finer particle sizes of less than a micron than roller jar mills. If you need to grind your material to a very fine powder, a planetary ball mill is the better option.

Efficiency: This is most important factor for consideration when choosing Planetary ball mills and roller mills. Planetary Ball mills are also more efficient than roller jar mills. They can grind materials more quickly and evenly.

Total volume of material: Planetary ball mills have a smaller capacity than roller jar mills. If you need to grind a large amount of material, a roller jar mill is the better option. Across International offers standard planetary ball mills that can accommodate up to 4x1000ml Planetary ball mills

Cost: Planetary ball mills are more expensive than roller jar mills. If you are on a budget, a roller jar mill may be the better option.

In general, planetary ball mills are the better choice for applications that require a fine particle size and high efficiency. Roller jar mills are a better choice for applications that require a large capacity and a lower cost.

Here is a table summarizing the key differences between planetary ball mills and roller jar mills:

|

|

|

Feature |

Planetary Ball Mill |

Roller Jar Mills |

|

Final particle size |

Finer |

Coarser |

|

Efficiency |

More efficient |

Less Efficient |

|

Total volume of material |

Smaller capacity |

Larger Capacity |

|

Cost |

More expensive |

Less Expensive |

|

Contamination |

Less likely |

More likely |

|

Safety |

Very Safe |

Less Safe |

Ultimately, the best way to choose between a planetary ball mill and a roller jar mill for powder milling applications is to consider your specific needs and requirements.

Planetary ball mills may be used for mixing, homogenizing, fine grinding, mechanical alloying, cell disruption, small volume high-tech material production, and even colloidal grinding. They are the ideal wet/dry milling tools for acquiring research samples with high efficiency and low noise. Vacuum jars may be used to process samples within a vacuum environment.

Custom-built planetary ball mills that meet customers’ specific requirements are also available upon request. If you don’t see a planetary ball mill or roll jar mill that you want on our website, please contact us to speak with a Tech Specialist.