We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Buying Guide of Biosafety Cabinets

Most laboratory equipment performs an active function. For example, a centrifuge separates liquids, and CO2 incubators grow tissue cultures. In comparison, role of a biosafety cabinet, while critical, might seem passive.

Biosafety cabinets (BSCs) do not perform any one direct function, but rather it prevents adverse conditions from occurring. BSCs cabinets are meant to prevent harm to employee health and contamination of the environment. Some also prevent contamination of the product in the work zone.

Biological Safety Cabinets function by causing air to move in precise patterns, as well as filtering air to eliminate particulate matter. This ability requires sophisticated engineering in such areas as the fluid dynamics of airflow, ergonomics of usability, the design of the enclosure, and electrical design of motors, blowers, and control systems

Biosafety Cabinet Class II, Type A2 is given its Class and Type based on performance criteria developed by performance standard NSF/ANSI 49.

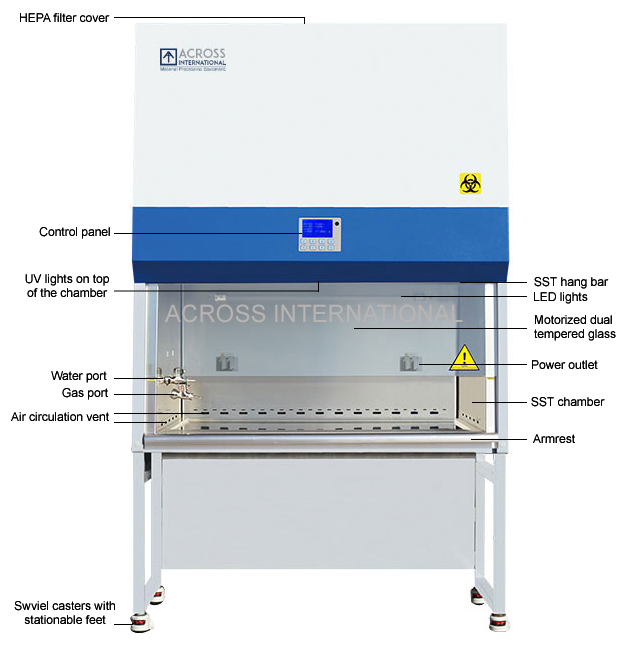

A Class II, Type A2 Biosafety Cabinet (BSC) provides personnel, product, and environmental protection through filtered air, laminar or unidirectional air, and a motor blower. Room air is drawn in through the front grill of the cabinet.

The air is pulled under the work surface and through a back wall plenum through a motor blower. This contaminated air is then pushed into the central plenum, where a small portion (30%) of air is exhausted out of the top of the cabinet through a HEPA filter. The remaining air (70%) is re-circulated back into the work zone through a HEPA filter in a laminar (unidirectional) pattern.

The air then splits on the work surface, pulled through the back wall grill, around the edges of the work surface, and back through the front airflow grill, where it is pulled under the work surface to start the air recirculation process.

Personnel protection is created by an air barrier at a minimum of 100 FPM (0.51 m/s) at the front of the cabinet, where laboratory and work surface air are pulled into the front air grill.

Product protection is created through laminar airflow over the work surface. The unidirectional pattern minimizes cross-contamination.

Environmental protection is created by filtering the exhaust airflow through a HEPA filter.

A Class II, Type A2 BSC used for work with minute quantities of non-flammable or explosive volatile toxic chemicals and tracer amounts of radionuclides required as an adjunct to microbiological studies must be exhausted through properly functioning exhaust canopies.

To run a modern healthcare, biological, chemical, medical research, pharmacy, or pharmaceutical lab, a manager should understand the capital equipment employed regularly. The more thorough the knowledge of each device, the more efficiently the lab manager can plan for the implications of deployment, maintenance, repair, and replacement.

To evaluate the lab’s needs and plans in conjunction with all people at the organization who have responsibilities for or interests in the adoption and use of a BSC. Speak with the technical experts from Across International of biosafety cabinets. Ask about the specific solutions that are available, the likely maintenance requirements, and fully loaded lifetime costs.