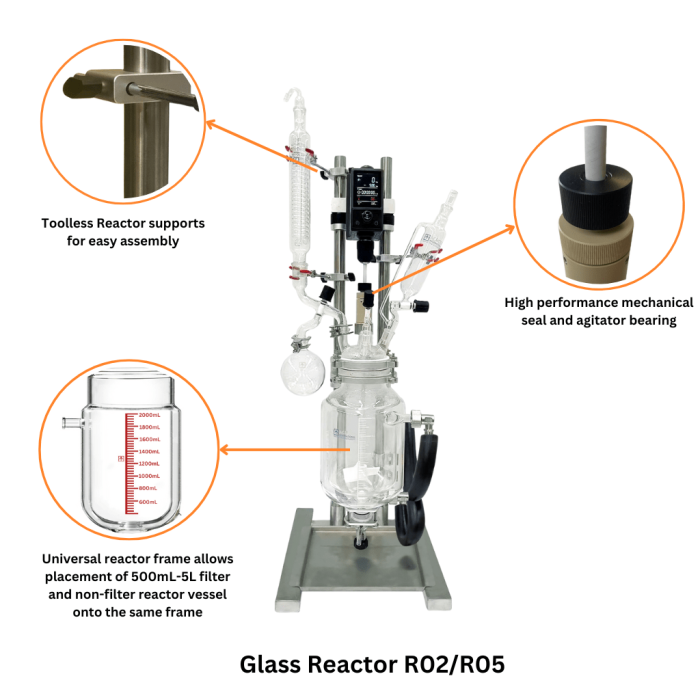

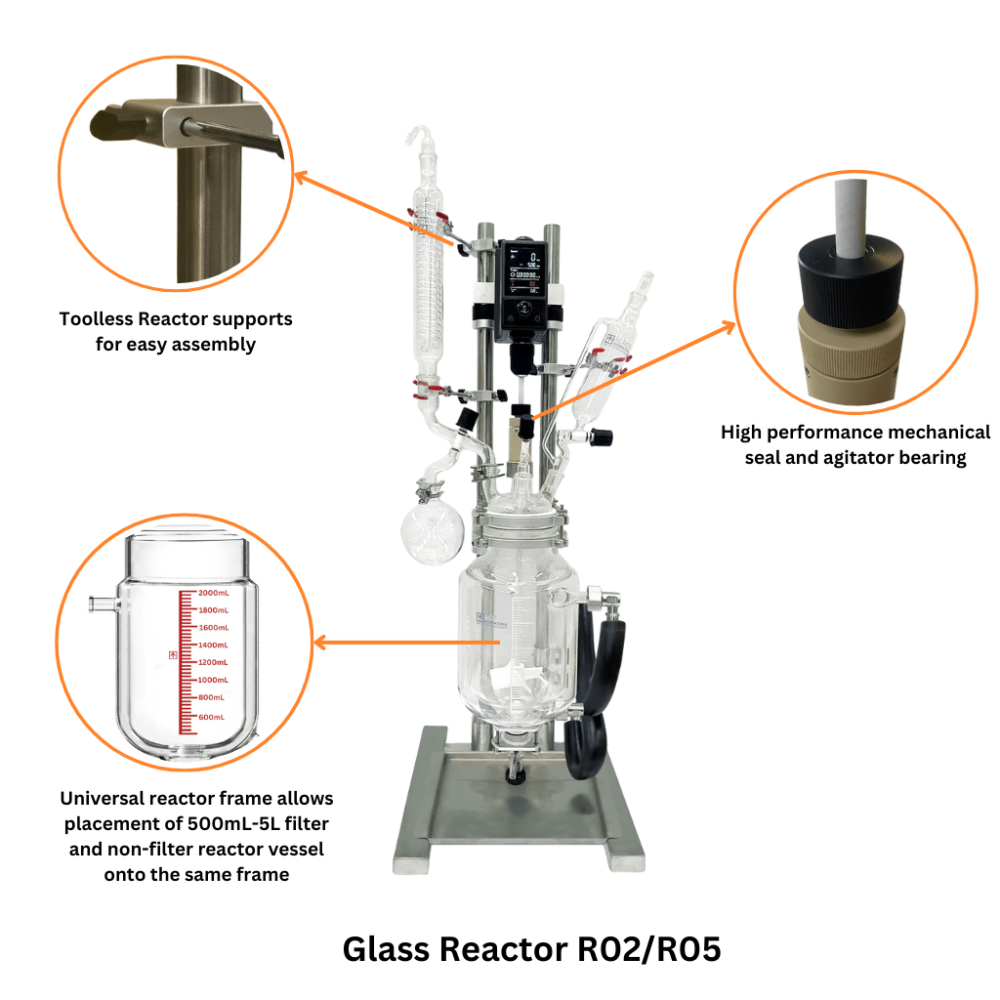

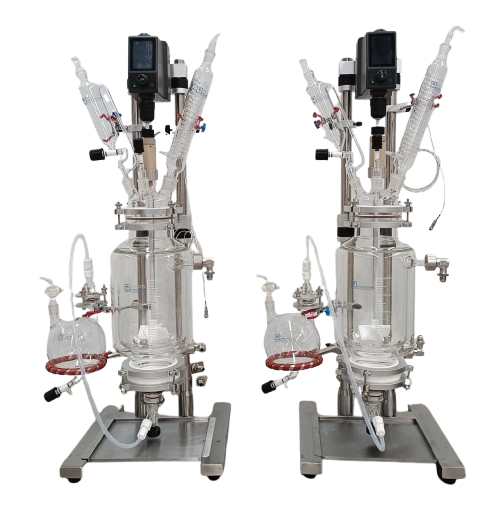

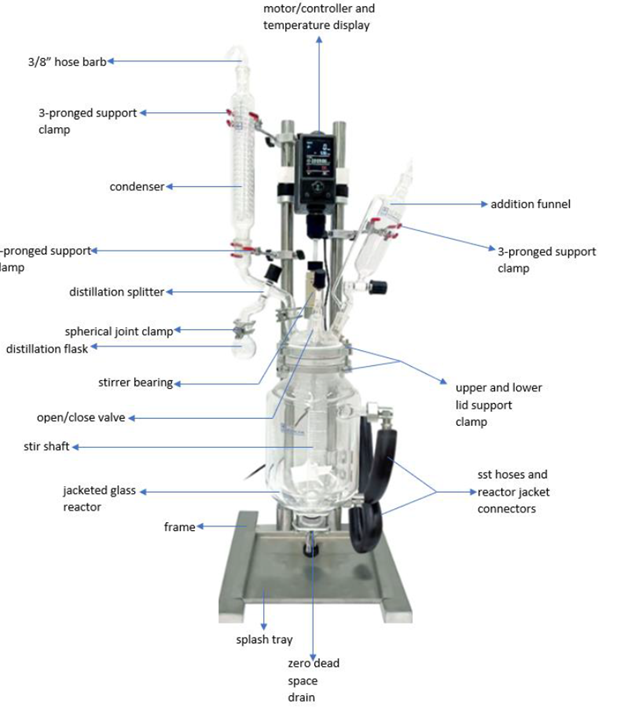

Introducing the Ai R-series single glass reactors bench top reactors. Both the 2L and 5L reactor vessels can be used on the same frame, allowing for greater flexibility and customizability. Reactors are designed for synthetic reaction of different types of materials in a controlled temperature and vacuum environment. Each reactor features adjustable stirring speeds and a constant pressure feeding funnel that allows you to add material to the vessel at a uniform and controlled speed. The built-in condenser makes it possible to recover some materials, also at a controlled rate of speed.

Features

- Solvent-resistant PTFE on all sealing components ensures long time durability and operation.

- All glassware is hand-made from food grade high borosilicate glass that is corrosion-resistant.

- Adjustable stirring rate provides great torque or high speed.

- Wide range of temperature operations, from -120C to -200C.

- Large condenser cooling surface for exceptional condensation performance.

- Rugged stainless steel reinforced PTFE stirrer with anchored agitator, suitable for a wide range of viscous materials.

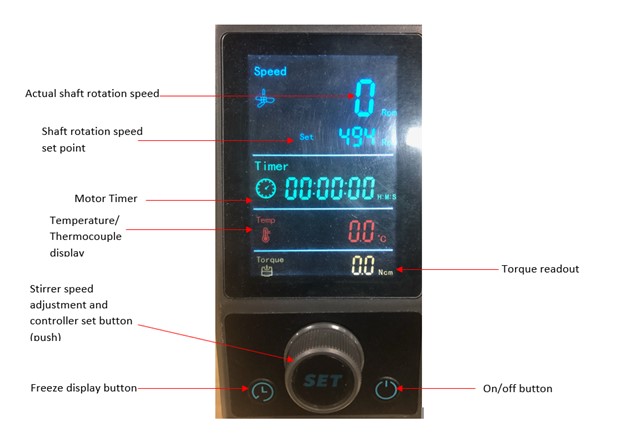

- Visual operation with digital speed and temperature displays.

- Easy swap between 2L and 5L capacity (additional vessel required, not included)

- One year warranty and US-based parts, service, and support.

Your safety is important to us! Please use caution when operating. Users of glass reaction equipment must take all necessary precautions to avoid contact with rotating parts, particularly the entanglement of loose clothing, hair, necklaces, or other jewelry. Under these circumstances, the winding action of the rotating parts can draw the user(s) into the apparatus, resulting in the breakage of glassware, burns, and/or chemical exposure. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

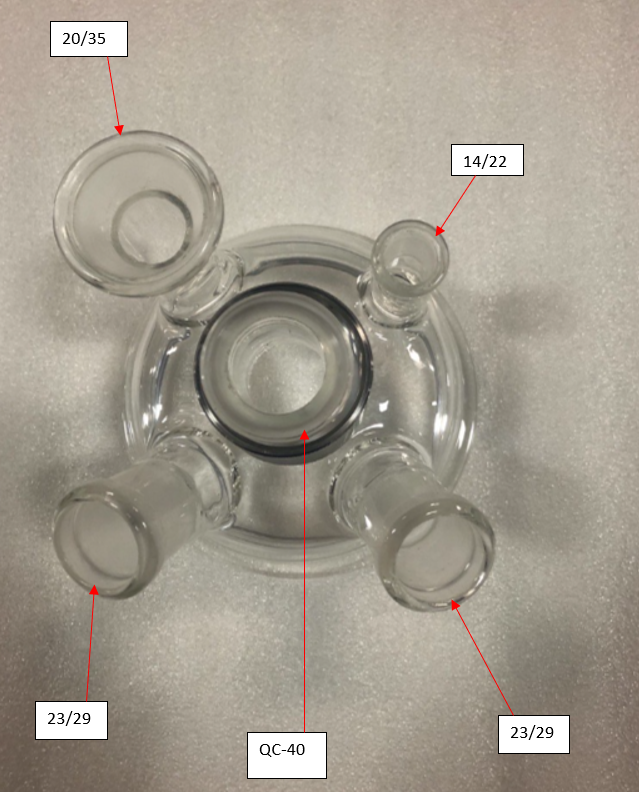

Lid Port Configuration for R02 and R05

FAQ for Glass Reactor Series

- When do you recommend using the different impeller types that you have listed on the website?

The two different impeller types that we have is the pitched blade and the anchor agitator. It is recommended to use the pitched impeller for low viscosity solutions such as aqueous solutions and organic solvents. The anchor impeller is best used for higher viscosity applications such as thick oils, resins, and polymers. - How do I clean my reactor?

The most effective and efficient way to clean your reactor would be by using the clean in place kit shown below paired with a pump capable of achieving between 10-20 psi. - What is the best way to fill the reactor?

The best way to fill the reactor is to pull vacuum on the reactor from the condenser, and use either the stopcock on the lid or other fitting connected to a hose to pull the suck fluid into the reactor. As long as the other end of the tube is submerged in liquid and the pressure inside of the reactor is less than atmospheric pressure, fluid will enter the reactor. - What are the materials of construction for the reactor’s wetted parts?

3 borosilicate glass and PTFE - How long is the warranty period and what does it cover?

The length of the warranty is one year, and it covers manufacturing defects, - What accessories come with the reactor?

The reactor will come with everything listed on the standard package for the unit that will be purchased. If purchasing an entire turnkey, please see the turnkey’s standard package. The standard package can be found on the web listing at Across International’s website under the standard package tab. - Where can I find technical information about the Across International reactor?

Technical information can be found on the Across International website under the specifications tab. If further technical information is needed, please reach out to the sales team via email or phone at Across International: [email protected] or 888-980899. - What are the lid port sizes for my glass reactor?

The lid port sizes will vary depending on reactor type. Any port not labelled on the drawing is specific to Across International, take note that the QC-35 is also specific to Across International but clamps and adapters can be bought from Across International as needed for all lid adapters. - Will these sizes fit standard American ground glass joints? If so which ones will fit?

Please see the table below for a detailed description of which Across International glass reactor joints will fit the standard American ground glass joints:

|

Across International Joints Conical Joints |

Compatible American Standard Conical Joints |

|

40/38 |

40/50 |

|

34/35 |

34/45 |

|

24/29 |

24/40 |

|

14/23 |

14/35 |