Call For Price

The Spark Plasma Sintering (SPS) process involves loading metal and other powders into a mold typically composed of graphite and other materials. Energized electrodes and upper and lower die punching are then utilized to apply specific sintering power supply and pressing pressure to the powder. This method combines thermoplastic deformation and cooling, representing a novel approach in powder metallurgy sintering to produce high-performance materials.

Characterized by sintering under pressure, discharge plasma sintering benefits from the plasma generated by pulse current and pressurization during the process, effectively lowering the sintering temperature of the powder. Notably, its low voltage and high current features enable rapid and dense powder sintering.

Advantages of this method include rapid heating, shortened sintering duration, reduced sintering temperature, uniform grain formation, control over the fine structure of the sintered body, achieving high material density, ease of operation, high reproducibility, safety, reliability, space efficiency, energy conservation, and cost-effectiveness.

Principle Advantages

Besides benefiting from the conventional Electrical Discharge Machining (EDM) effects like discharge shock pressure and Joule heating, this technology further accelerates sintering by leveraging the spark discharge phenomenon. This phenomenon, characterized by instantaneous high-temperature plasma, occurs between powders during the initial stage of pulse discharge. By applying the sintering promotion effect generated by a specialized power supply control device to the powder sample, rapid sintering is achieved.

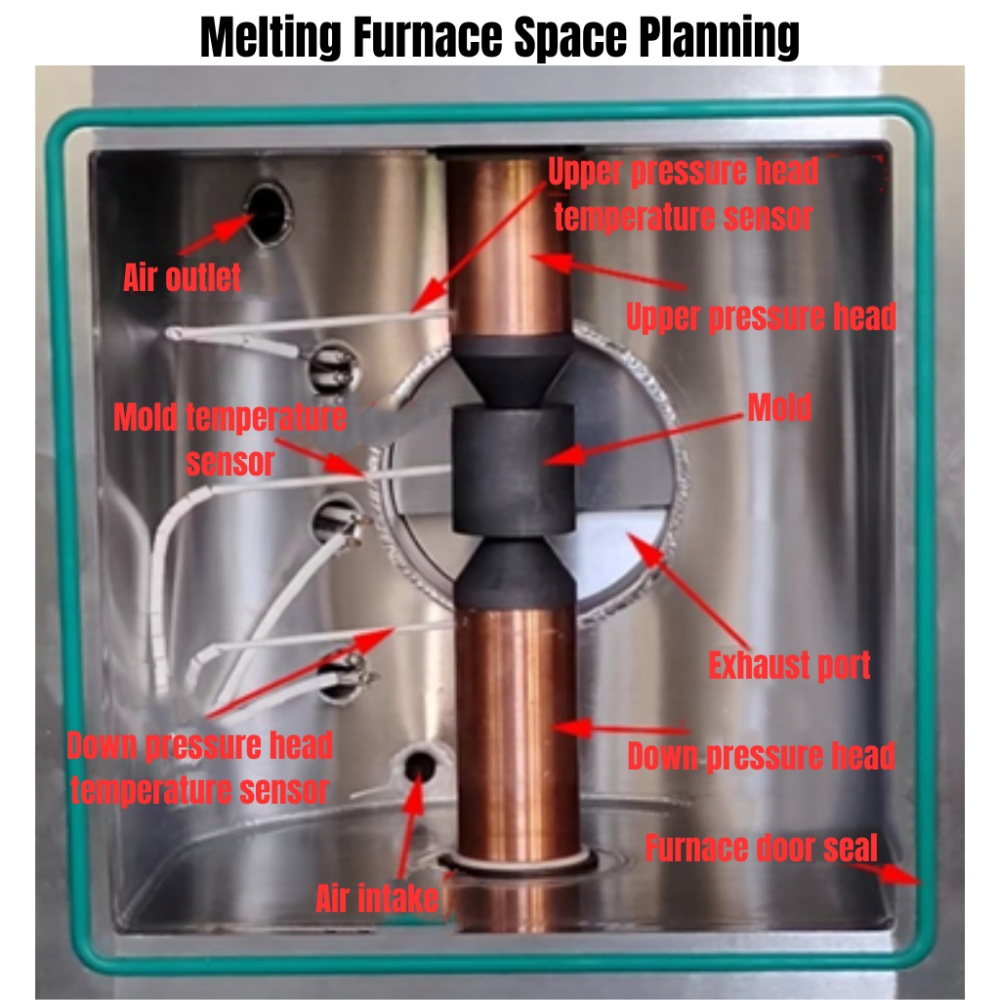

- The chamber space is generously sized and designed for user-friendly operation.

- Thermocouples are incorporated to monitor the temperature of both upper and lower pressure heads. In the event of any anomaly, users can promptly observe it, shut down the equipment, and prevent damage.

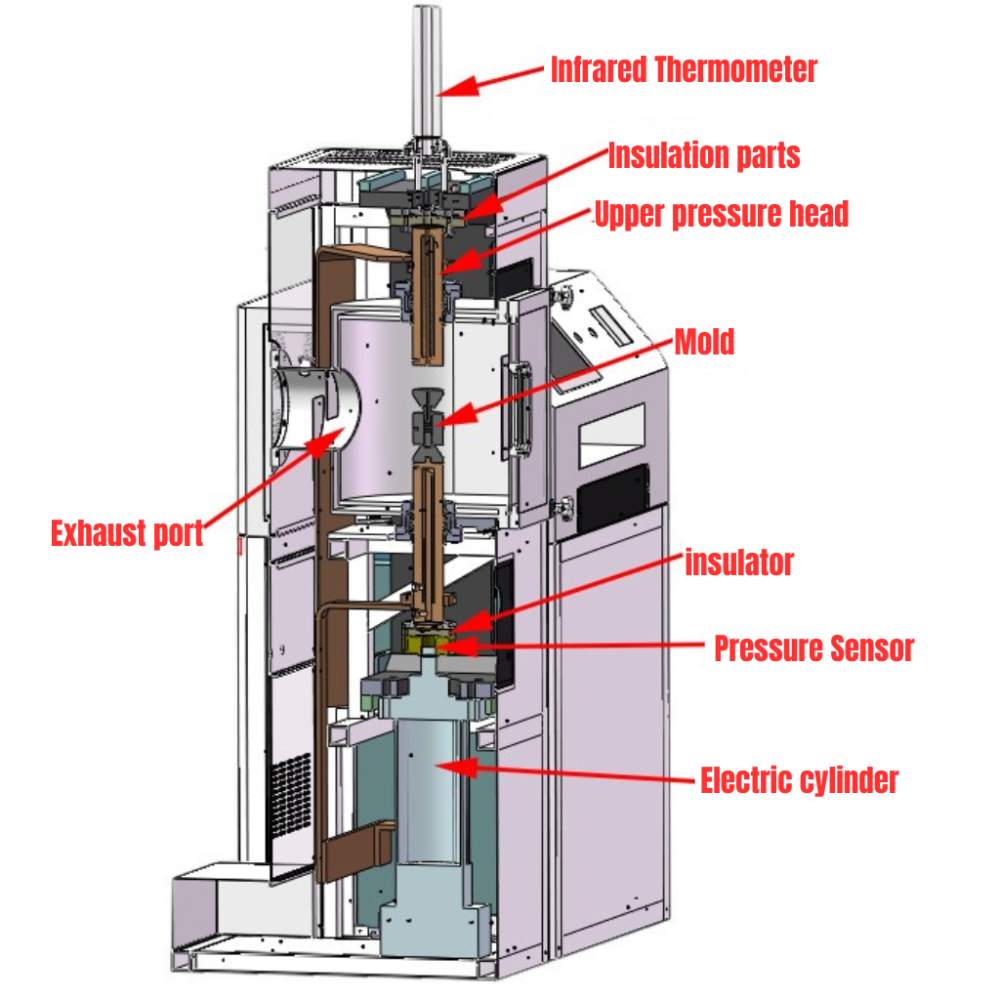

- An infrared thermometer is utilized to measure furnace temperature from the top, ensuring superior accuracy compared to side temperature measurement.

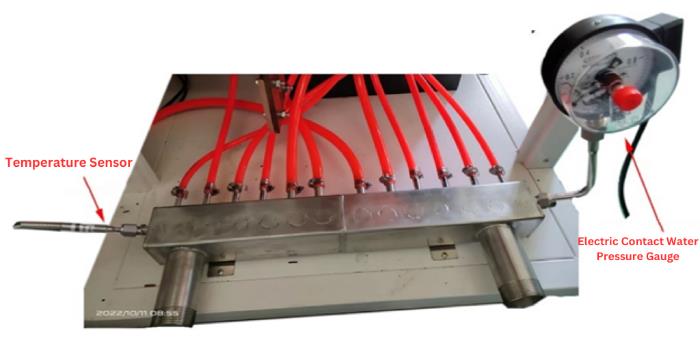

- The waterway system includes temperature detection and water pressure monitoring. In case of any irregularities, alerts are triggered, and heating is automatically shut off.

- An explosion-proof system is in place. If cavity pressure exceeds the set threshold, alarms sound, and heating is deactivated.

- Comprehensive protection features such as over-temperature, over-voltage, over-current, under-voltage, and couple breaking protection are incorporated, along with display functionality for added safety and convenience.

Control System

The control system consists of a PLC program combined with a touchscreen, featuring our company’s independently developed control system built into the touchscreen. All operations are integrated into the touchscreen, providing a user-friendly human-machine interface with one-touch operation, making it simple and convenient to use.

Internal Chamber

Pressurization System

Eurotherm 3504 Programmable Temperature Controller

500-Step Programmable Temperature Control: Supports 8 groups of PID intelligent adjustment.

Over-Temperature and Thermocouple Disconnection Protection: Automatically cuts off the furnace heating circuit in the event of over-temperature or thermocouple disconnection. (When the furnace temperature exceeds 1820°C or thermocouple burns out, the AC relay on the main circuit will automatically disconnect, shutting off the main circuit. The "ON" light on the panel turns off, and the "OFF" light turns on, providing essential furnace protection).

Supports Various Communication Interfaces: Compatible with Modbus, Ethernet, Profibus, and Device net, enabling integration with any PLC or upper-level system.

Power Failure Protection: After a power outage, upon re-powering, the furnace resumes heating from the temperature at the time of the outage, rather than from the initial set temperature.

Self-Tuning Temperature Adjustment: The controller includes an automatic temperature self-tuning feature.

Water Manifold

It consists of pipes and related devices. After entering through the main cooling water pipe, the water is distributed via various branch pipes to the furnace body, furnace cover, furnace base, water-cooled electrodes, and other areas that require cooling water, then collected and discharged through the water outlet. The cooling water circulation pipes relate to high-temperature-resistant rubber hoses. An electric contact pressure gauge is installed on the main inlet pipe; if the water pressure falls below 0.2 MPa, the heating is automatically cut off. A temperature sensor is installed on the main outlet pipe; if the temperature exceeds 45°C, the heating is automatically cut off.