Ultrasonic homogenizers, the modern version of "mortar and pestle", they can disrupt tissues and cells through cavitation and ultrasonic waves. Basically, an ultrasonic homogenizer has a tip which very rapidly vibrates, causing bubbles in the surrounding solution to rapidly form and collapse. This creates shear and shock waves which tear apart cells and particles.

Ultrasonic Homogenizers are recommended for homogenization and lysis of laboratory samples that do not require traditional grinding or rotor-stator cutting techniques for processing. Small and large ultrasonic probes are used in a variety of sample volumes to be processed. A solid probe allows for less chance of sample loss and cross-contamination between samples.

Sonication is the act of applying sound energy to agitate particles in a sample, for various purposes. Ultrasonic frequencies (around 20 kHz) are usually used, leading to the process also being known as ultrasonication or ultra-sonication. In the laboratory, it is usually applied using an ultrasonic bath or an ultrasonic probe, colloquially known as a sonifier.

Sonication can be used for the production of nanoparticles, such as nanoemulsions, nanocrystals, liposomes and wax emulsions, as well as for wastewater purification, degassing, extraction of plant oil, extraction of anthocyanins and antioxidants, production of biofuels, crude oil desulphurization, cell disruption, polymer and epoxy processing, adhesive thinning, and many other processes. Sonication is also commonly used in nanotechnology for evenly dispersing nanoparticles in liquids.

Now including a new large-capacity filter ideal when working with larger nanoemulsion volumes. The large-capacity filtration system comprises a stainless-steel housing (one-time purchase) and a replacement cartridge (consumable). Each cartridge is capable of handling significantly larger nanoemulsion volumes than the previous filters and it can be cleaned and reused many times before it needs to be replaced (so not only more efficient but also lower cost of ownership)."

ISP-3600 in Continuous Mode

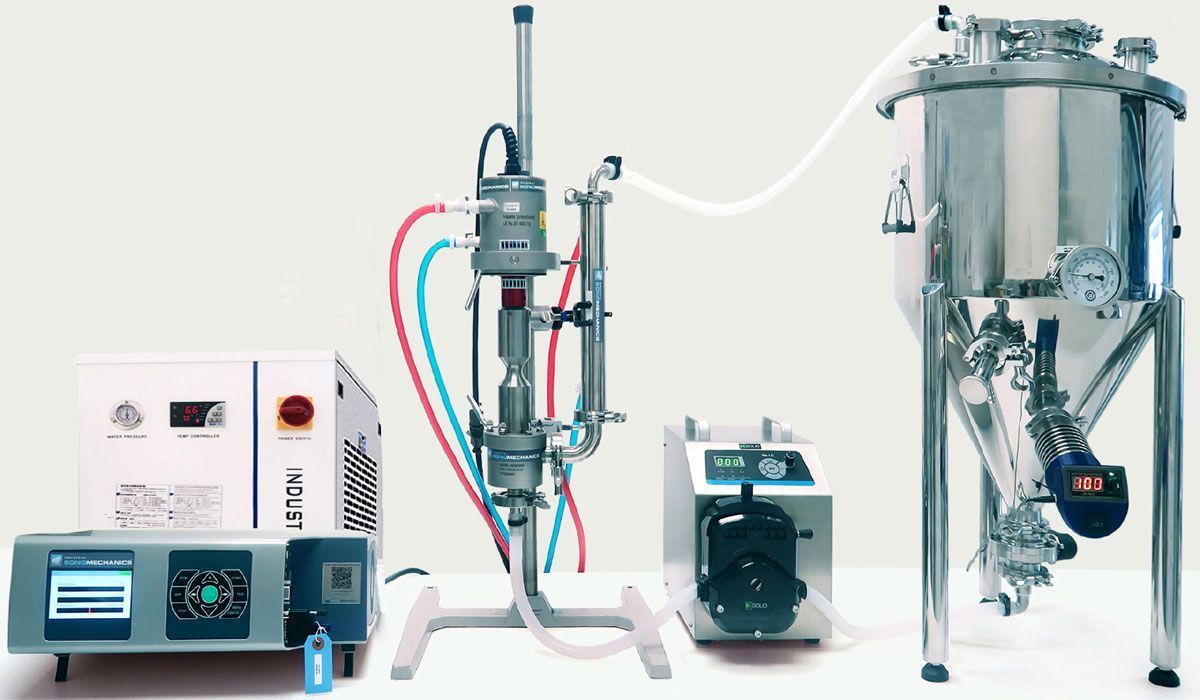

The ISP-3600 industrial-scale ultrasonic liquid processor from Industrial SonoMechanics

The ISP-3600 ultrasonic liquid processor is designed for industrial-scale production. It is suitable for working with liquid volumes above 1 L, with no upper limit.

Features

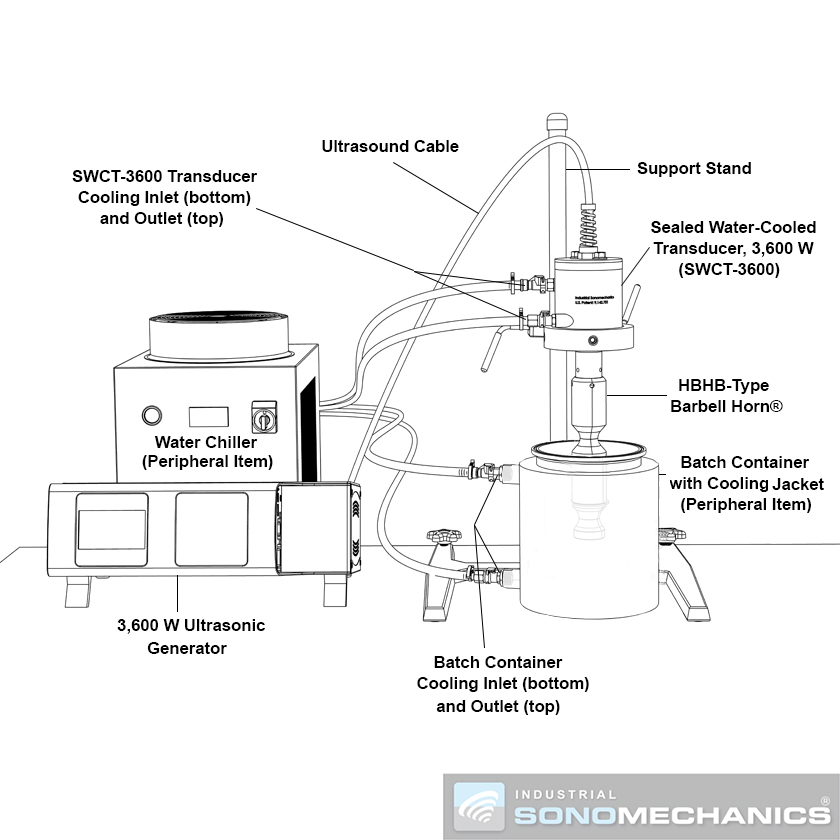

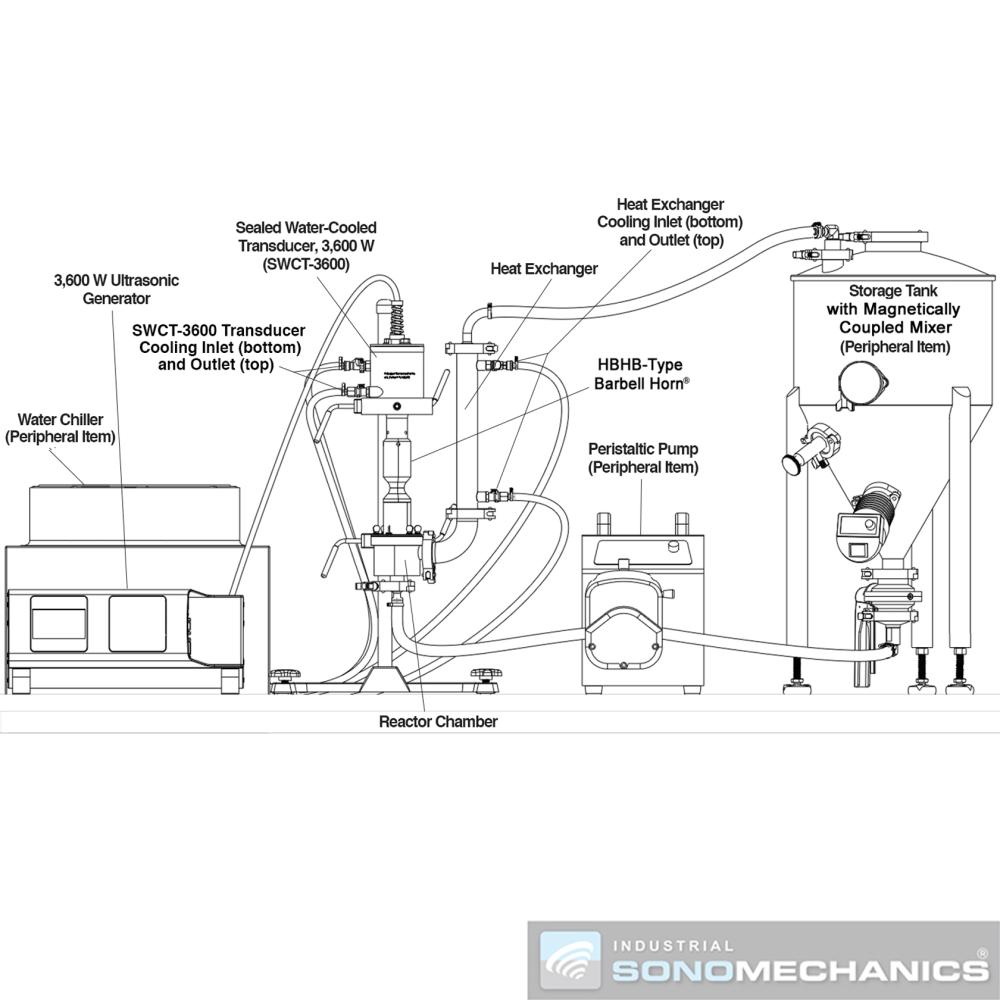

- The ISP-3600 ultrasonic liquid processor is most commonly supplied with a 3600 W ultrasonic generator, water-cooled transducer, half-wave booster half-wave Barbell Horn® (HBHB), and flow-through reactor chamber (flow cell). Optional items include a half-wave Barbell Horn® (HBH) and support stand.

- The ISP-3600 processor can be used in batch and flow-through configurations (see schematics on the left). Details are available under the SPECIFICATIONS tab.

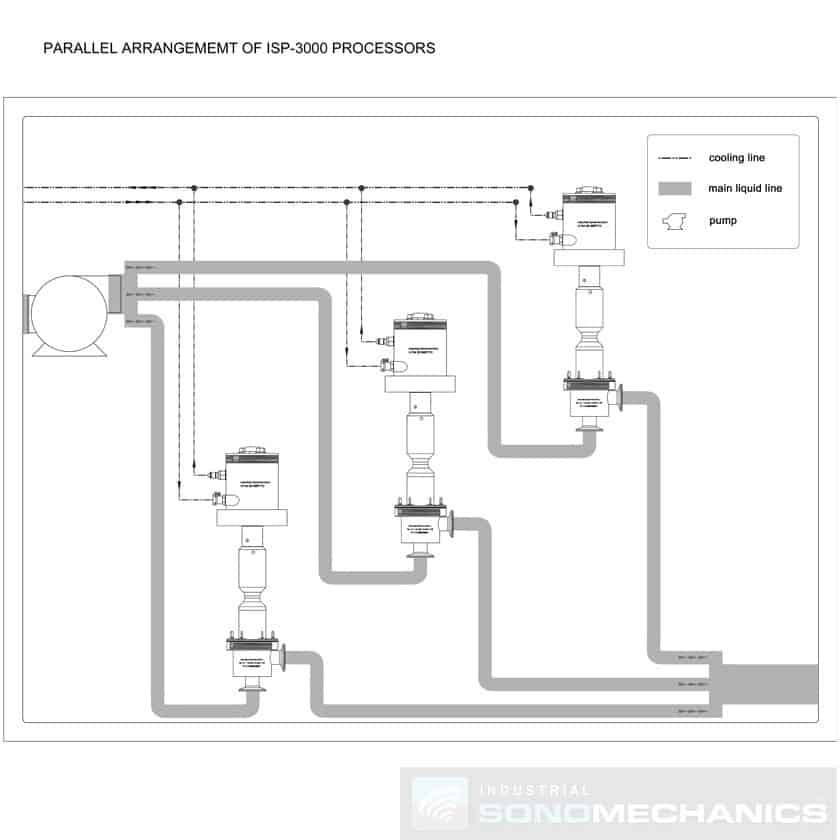

- The ISP-3600 processor utilizes patented Barbell Horn® Ultrasonic Technology (BHUT), which makes it possible to generate extremely high ultrasonic amplitudes at any scale of operation. With the ISP-3600, any process optimized with our smaller units, the LSP-600 or BSP-1200, can be directly scaled-up to an industrial production environment, while maintaining the same processing conditions and reproducible results. Further scale-up is possible by placing several ISP-3600 processors in parallel and/or in series (see schematics on the left).