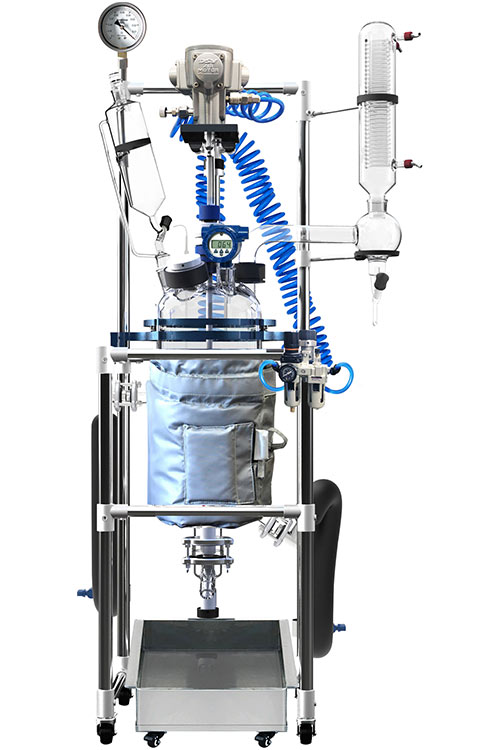

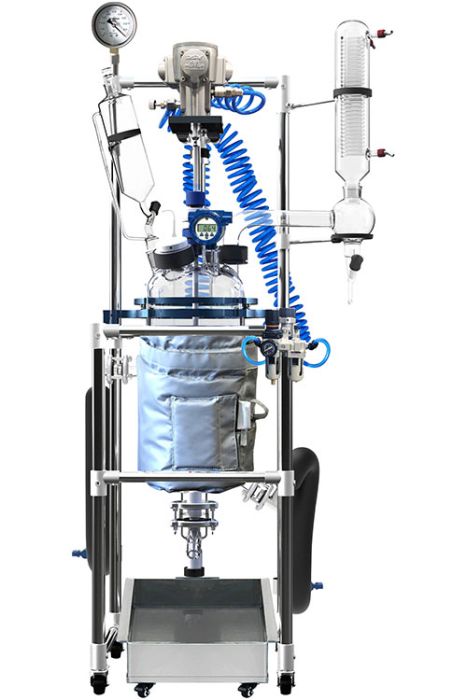

Ai R-series single/dual jacketed glass reactors are designed for synthetic reactions of different types of materials in a controlled temperature and vacuum environment. Each reactor features adjustable stirring speeds and a constant pressure-feeding funnel that allows you to add material to the vessel at a uniform and controlled speed. The built-in condenser makes it possible to recover some materials, also at a controlled rate of speed.

Features

- Now includes a FREE high quality thermo insulation jacket (a $399 value) with open/close viewing window and top/bottom adjustable drawstrings, specially designed and made for Ai glass jacketed reactors. These jackets will extend chiller life, allow you to go down to a lower temperature, and also cut your utility bill.

- Dual jacketed model allows you to draw vacuum from the outer jacket, thus protects your recirculating fluid temperature and gives you best control over your work. It also help prevents frost to form on the outside of the vessel, allowing you to see clearly into your material.

- Solvent-resistant PTFE on all sealing components ensures long time durability and operation.

- All glassware is hand-made from food grade high borosilicate glass that is heat/cold/corrosion-resistant.

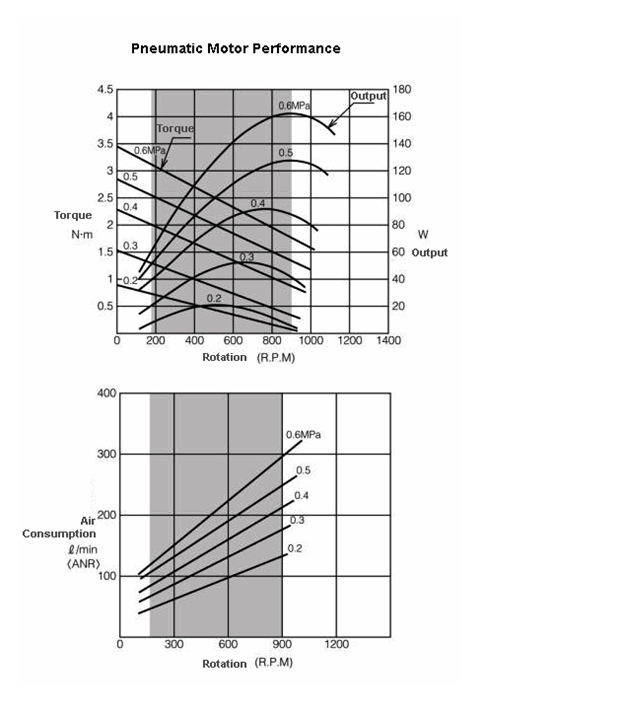

- Adjustable stirring rate provides great torque or high speed.

- Patented PTFE stirring rod bearing for reliable and quiet operation.

- Optional multi-layer stirring blades for optimal reaction results.

- Wide range of temperature operations, from -110F to 400F.

- Large condenser cooling surface for exceptional condensation performance.

- Rugged stainless steel reinforced PTFE stirrer with anchored agitator, suitable for a wide range of viscous materials.

- Heavy duty stainless steel supporting framework with lockable casters for mobility and stability. (whole support and glass vessel shipped pre-assembled)

- One year warranty and lifetime US-based parts, service, and support.

Your safety is important to us! Please use caution when operating. Users of glass reaction equipment must take all necessary precautions to avoid contact with rotating parts, particularly entanglement of loose clothing, hair, necklaces, or other jewelry. Under these circumstances, the winding action of the rotating parts can draw the user(s) into the apparatus, resulting in breakage of glassware, burns, and/or chemical exposure. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

.jpg)