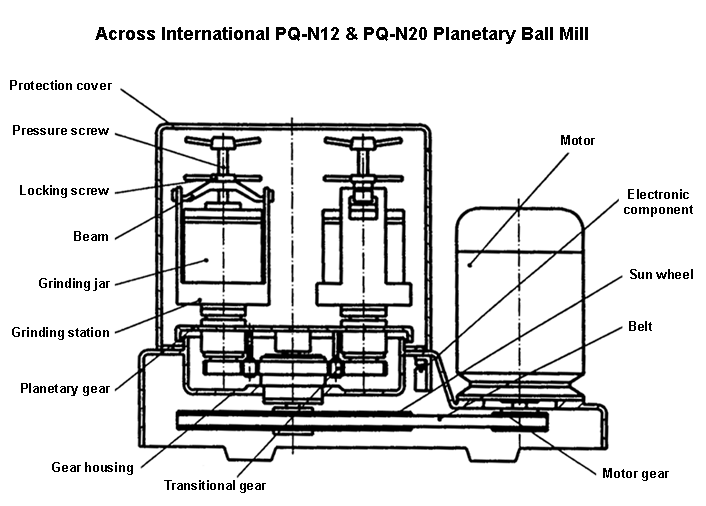

PQ-N20 series planetary ball mills may be used for mixing, homogenizing, fine grinding, mechanical alloying, cell disruption, small volume high-tech material production and even colloidal grinding. They are the ideal wet/dry milling tools for acquiring research samples with high efficiency and low noise. Vacuum jars may be used to process sample within a vacuum environment.

PQ-N20 planetary ball mills have four grinding stations arranged on the "Sun Wheel" of the planetary ball mill. When the Sun Wheel rotates, the grinding balls inside the jars are subject to superimposed rotational movements, known as Coriolis Forces. The difference in speeds between the grinding balls and jars produce an interaction between frictional and impact forces, which release high dynamic energies. Minimum granularity of the final product can be as small as 0.1 micron.

A timer controls running time from 1 to 999 minutes; it also controls jars' direction of rotation and intervals. We offer various sizes of grinding jars and grinding balls in different materials in our ball mill accessories section. Depending on your application, the material your grinding media is made from may be imperative to achieving accurate results.

Grinding methods

- Single direction without timing (samples need long or non-stop milling)

- Single direction with timing (samples need to be milled in one direction for a designated amount of time before automatic shutdown)

- Bi-direction with timing (samples need to run clockwise for 1.5 hours, then counter-clockwise for another 1.5 hours and so on, for 15 total hours, before the machine shuts down itself)

- Single direction with paused interval and timing (i.e. samples need to run for 0.5 hour, then pause for 1 hour, then run for another 0.5 hour in same direction and pause for another 1 hour, for 10 cycles before auto shutdown)

- Bi-direction with paused interval and timing (samples need to run clockwise for 0.8 hour, pause for 0.5 hour, then run counter-clockwise for 0.8 hour, for 20 cycles, before auto shutdown)

Features

- High uniformity and excellent repeatability

- Fast rotational speed, high efficiency and fine granularity

- Four samples with different sizes and materials in one experiment

- Leak-proof jars for wet grinding

- Large range of materials available for grinding media

- Gear-drive offers an effective solutions to problems caused by belt driving, such as belt creep and belt abrasion

- Low center of gravity, good rigidity, compact structure, low noise, safe and reliable operation

- Adjustable height

- Safety switch ensures automatic shut down if cover is opened during operation

.jpg)