Please call us for the price (Quote), thank you.

Ai RTF1200AF series top-open tube furnaces feature Ai custom made mechanical material auto feeding system with adjustable speed. These furnaces come with the famous Kanthal (Sweden) spiral wire coils embedded in Mitsubishi (Japan) high-quality grade 1500 alumina fiber insulation. A double-walled steel internal housing helps minimize heat loss to the exterior surface.

Furnace operation is controlled by Eurotherm (UK) multi-segment digital controller, allowing the user to connect to a PC for remote control and monitoring of the furnace.

Controller Options:

Eurotherm 3504: 50 segments (ramping and dwelling)

Features

- Ai custom made mechanical material auto feeding system with adjustable speed.

- Top-open furnace chamber for fast and easy tube access.

- Eurotherm microprocessor based self-tuning PID controller provides optimum thermal process with minimal overshoot.

- Built-in computer interface.

Safety

- Overheat protection shuts down the furnace if temperature is outside of acceptable range (refer to controller's manual) or when the thermocouple is broken or malfunctions.

- Power failure protection resumes furnace operation right after the point of failure when power is reestablished.

- Limit switch turns off furnace once top is open.

Warning! NEVER fill furnace with explosive gases, including Hydrogen, Carbon Monoxide and Methane.

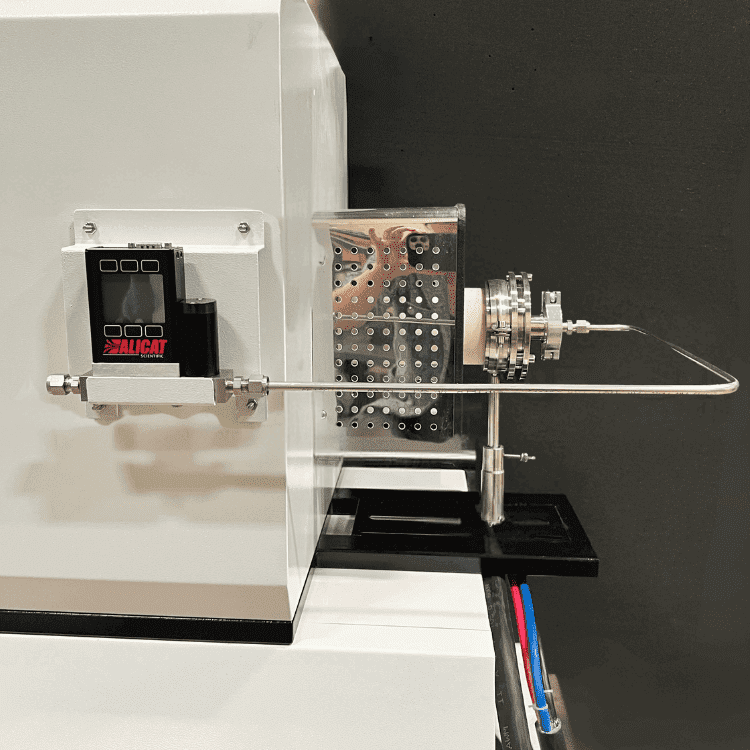

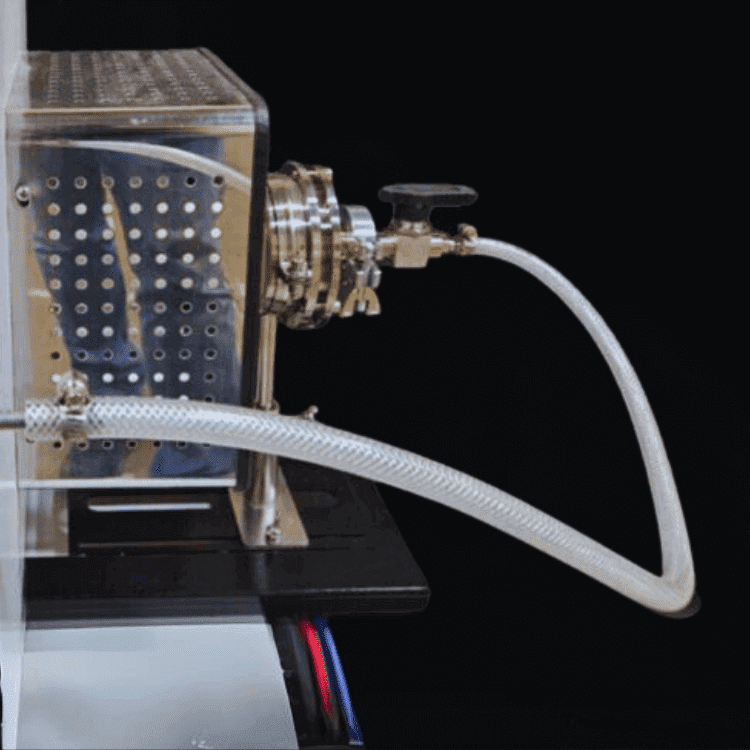

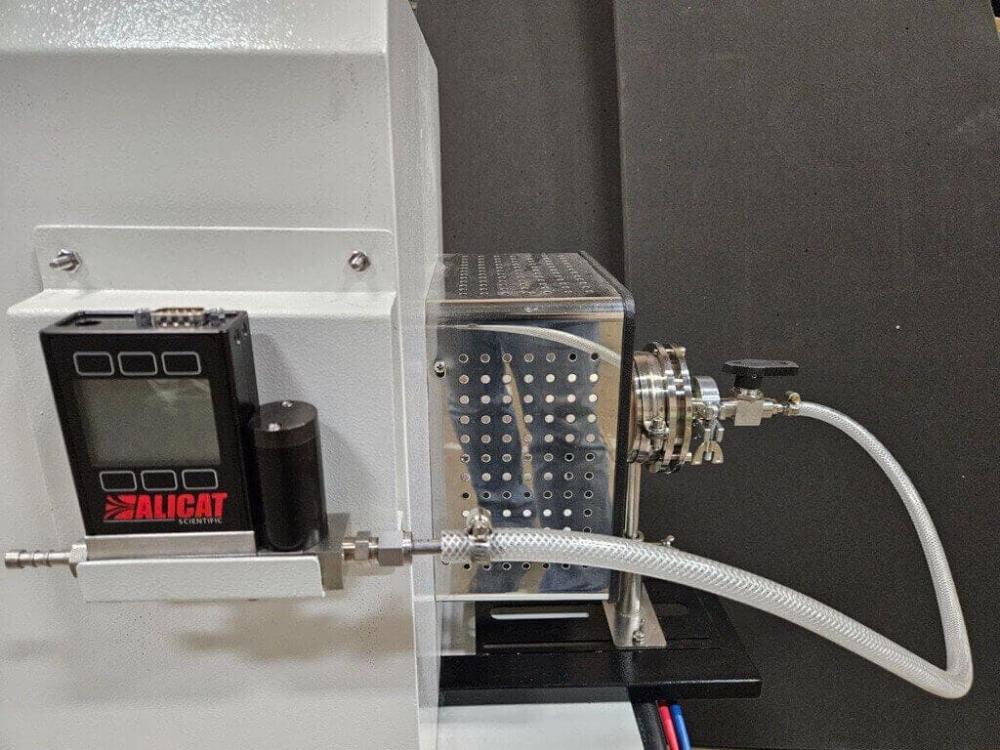

** All 3 pictures above for setup is for reference only. Actual setup can be configured many different ways based on user preference. The bracket plate for the mass flow controller can be magnetically attached and detached from the surface for ease of use **

Tubing sold separately

.jpg)

.jpg)

.jpg)